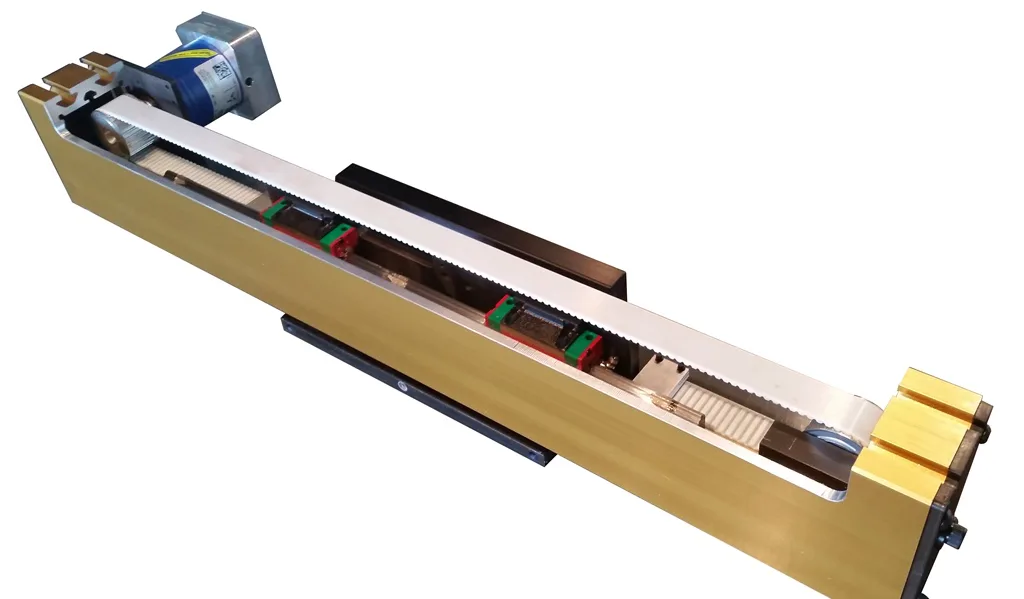

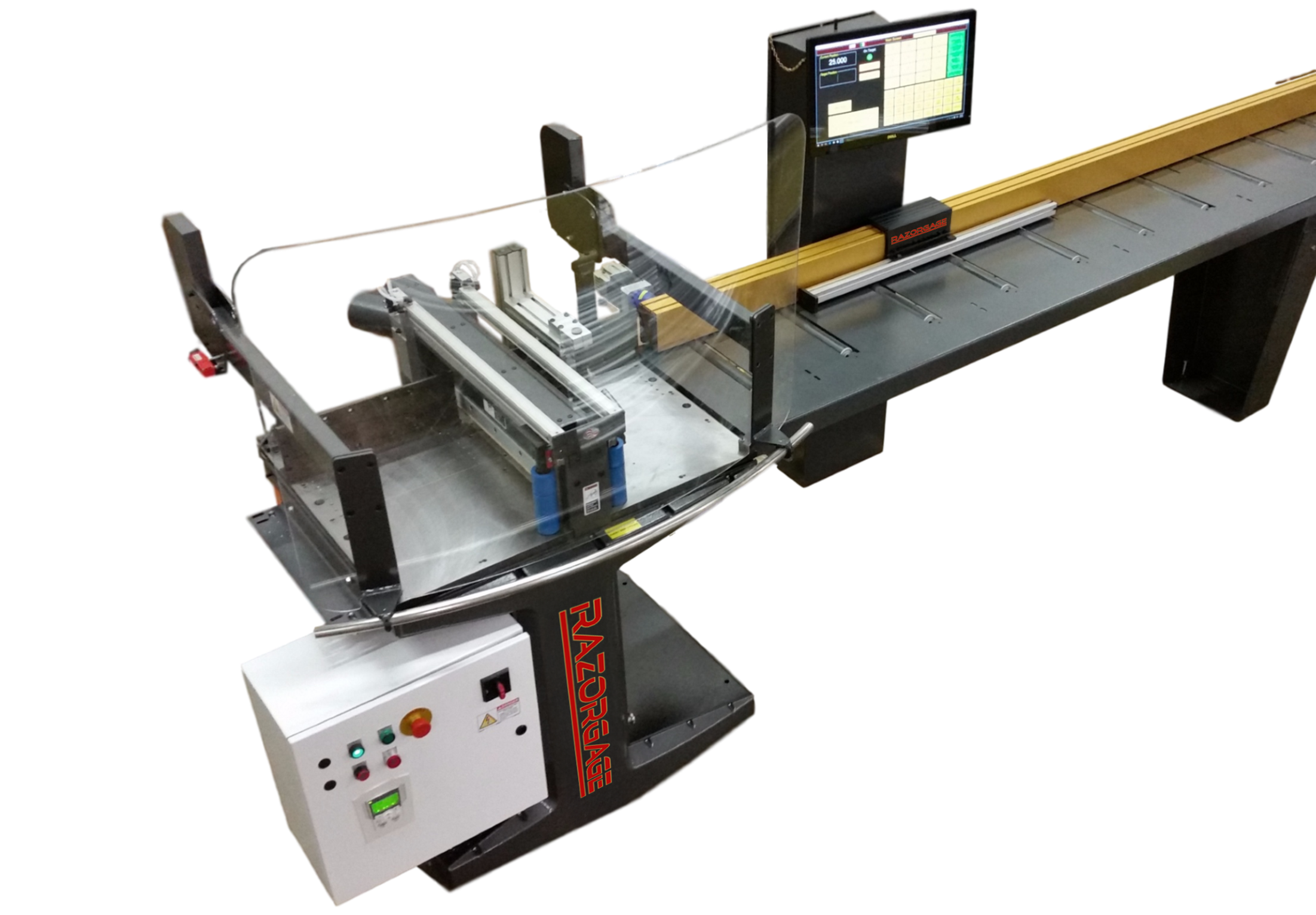

Why is an Automatic Chop Saw Better for Large Projects?

When working on large construction or woodworking systems, effectiveness and perfection are critical. The Automatic chop saw has become a favored tool for professionals handling demanding tasks because it streamlines cutting processes while perfecting overall delicacy. Unlike homemade tools, an automatic model reduces mortal trouble, minimizes crimes, and allows for harmonious productivity. Large systems frequently bear repetitious slice, speed, and dependable performance, all of which can be achieved with advanced slice technology.

1. Precision Cutting for Harmonious Results

Large- scale systems demand uniformity in every cut. An automatic chop saw delivers high perfection by maintaining harmonious angles and confines across multiple pieces. This point ensures that each element fits impeccably into the final structure, avoiding crimes that could else lead to expensive adaptations. The automated medium eliminates the inconsistencies of homemade sawing, making it largely effective for systems where exact measures are critical. Precision in slice also contributes to better structural integrity and aesthetic quality in construction or woodworking.

2. Increased Effectiveness for High Workloads

Time effectiveness is vital when handling bulk material slices. An automatic chop saw allows druggies to reuse large volumes of wood, essence, or other accoutrements in a bit of the time compared to homemade styles. The automated functionality reduces fatigue and maximizes affairs, making it possible to complete systems ahead of schedule. In diligence where deadlines count, effectiveness is a significant advantage. The capability to program repetitious cuts ensures that workers can concentrate on other essential tasks while the machine maintains productivity.

3. Enhanced Safety Features

Working with a cutting outfit always carries pitfalls, but automatic chop saws are designed with advanced safety mechanisms. Features similar as blade guards, emergency stop buttons, and automatic arrestment systems minimize the chances of accidents. For large systems that bear nonstop slice, safety is n’t just an option it is a necessity. The automated operation reduces the need for constant homemade running of accoutrements , lowering the liability of driver crimes. This makes the work terrain safer, especially in busy construction or manufacturing settings.

4. Continuity and Trustability for Heavy Use

Large systems generally place heavy demands on tools, taking them to perform constantly over extended ages. Automatic chop saws are erected with robust accoutrements and advanced engineering, icing they can repel rigorous use without frequent breakdowns. Their continuity makes them suitable for large- scale artificial operations where trustability is essential. Unlike lower, homemade tools that may wear out snappily under pressure, an automatic system is designed to handle nonstop workloads with minimum conservation interruptions.

5. Versatility in Cutting Accoutrements

One of the main advantages of an automatic chop saw is its capability to cut through a wide range of accoutrements , including wood, aluminum, sword, and plastics. This versatility makes it ideal for large systems that frequently involve working with multiple accoutrements . The capability to acclimate settings and blades for different accoutrements saves time and reduces the need for multiple slice tools. This rigidity is particularly precious in diligence like construction, cabinetwork product, and essence fabrication, where systems frequently bear different slice tasks.

6. Reduction of Material Waste

Large systems involve significant investments in accoutrements , and waste reduction directly impacts profitability. Automatic chop saws contribute to minimizing waste by furnishing accurate and unremarkable cuts. miscalculations in slice can lead to unworkable pieces, but robotization significantly reduces similar crimes. This perfection ensures maximum material application, which is pivotal for cost operation in large- scale operations. By minimizing waste, these saws also contribute to further sustainable practices, aligning with ultramodern pretensions of reducing resource consumption.

7. Speed and Productivity Advantages

When design deadlines are tight, speed is essential. Automatic chop saws outperform homemade styles by offering briskly cutting cycles. Their capability to maintain nonstop, automated operations allows brigades to complete tasks hastily without immolating delicacy. This position of productivity is vital for diligence that calculates on mass product, as it ensures timely delivery without compromising on quality. The speed advantage also means smaller detainments and smoother design progression, making the overall workflow more effective.

8. Reduced Operator Fatigue

Homemade slices can be physically demanding, especially when repeated over long hours. Automatic chop saws ease the workload by performing the utmost of the heavy slice automatically. This reduces strain on workers, helping them maintain focus and energy throughout the design. lower fatigue also translates into smaller miscalculations, perfecting overall design issues. For large systems taking extended operation, this benefit is significant as it maintains a harmonious pace of work without overloading the pool.

9. Capability to Handle Complex Cutting Conditions

Not all large systems are straightforward; numerous bear intricate or angled cuts. Automatic chop saws are designed to accommodate similar complex conditions with malleable settings and programmable features. They can perform bevel cuts, miter cuts, and emulsion angles with perfection. This inflexibility eliminates the need for multiple tools or expansive primer adaptations, saving both time and trouble. For systems involving customized designs or detailed homestretches, this capability to handle complex cuts becomes a major advantage.

10. Long- Term Cost effectiveness

While the original investment in an automatic chop saw may be more advanced than homemade tools, its long- term cost effectiveness makes it worthwhile. Reduced labor costs, lower material waste, and minimum time-out contribute to overall savings during large systems. The continuity of these machines means they can serve for numerous times without frequent reserves. For large- scale operations, the cost effectiveness extends beyond the design itself, making it a strategic investment in long- term productivity and profitability.

Conclusion

Large systems bear tools that balance perfection, speed, safety, and trustability. An automatic chop saw offers all these advantages, making it the superior choice for demanding cutting tasks. Its capability to handle repetitive workloads, minimize waste, and ameliorate driver safety ensures that systems are completed efficiently and directly. As diligence evolves, the demand for robotization continues to rise, emphasizing the significance of opting tools that enhance productivity. For professionals managing expansive operations, Optimizing saws through robotization represents a step toward lesser effectiveness and long- term success.