Aluminum is one of the most versatile and widely used materials in today’s world. From construction and transportation to home décor and electronics, it has countless applications. However, raw aluminum on its own can be vulnerable to scratches, corrosion, and wear over time. This is where anodizing comes in. Among the different types of finishes, glossy anodized aluminum stands out because of its sleek, reflective, and durable surface. It not only enhances the appearance of aluminum but also significantly improves its strength and resistance to external factors like moisture and weather. Glossy anodized aluminum has become popular for use in furniture, architectural designs, electronics, and even in vehicles because it combines beauty with functionality. This article explores what glossy anodized aluminum is, how it is made, and why it is so valuable across different industries, helping you understand why this material is worth considering for various projects.

What Exactly is Glossy Anodized Aluminum

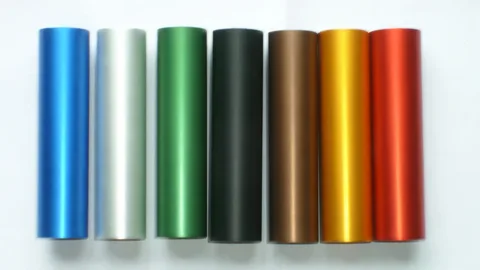

Glossy anodized aluminum is aluminum that has undergone a special electrochemical process known as anodizing, which creates a protective oxide layer on its surface. This layer is transparent and can be polished to achieve a shiny, reflective finish. Unlike paint or coating that sits on top of the metal, the anodizing process actually changes the surface of the aluminum itself, making it much more durable and long-lasting. The glossy version specifically involves additional polishing steps, which give it a mirror-like appearance. This makes it ideal for projects where both aesthetics and durability are essential.

How the Glossy Anodizing Process Works

The creation of glossy anodized aluminum involves several carefully controlled steps. First, the aluminum is thoroughly cleaned to remove any impurities, dirt, or grease. It is then submerged in an electrolytic solution, usually containing sulfuric acid, and connected to an electrical current. This causes a controlled oxidation process, where the surface of the aluminum reacts with oxygen to form a hard, protective layer of aluminum oxide. To achieve the glossy look, the surface is polished and sealed at the final stage, enhancing both its shine and resistance to environmental damage. This process ensures that the finish is smooth, reflective, and strong.

Durability Beyond Ordinary Aluminum

One of the most significant benefits of glossy anodized aluminum is its superior durability. The anodized layer is much harder than raw aluminum and protects the material from scratches, abrasions, and corrosion. This makes it particularly useful in environments where the metal may be exposed to water, air, or harsh weather conditions. For example, in coastal areas where salty air can quickly corrode untreated metals, glossy anodized aluminum remains strong and unaffected. Its resistance to wear and tear means that it can maintain its appearance and structural integrity for many years, even with minimal maintenance.

Aesthetic Appeal for Modern Designs

The glossy finish of anodized aluminum gives it a luxurious and modern look, making it popular in architectural and interior design. It reflects light beautifully and creates a clean, polished appearance that works well in contemporary settings. This material is often used for furniture frames, decorative panels, railings, and even in high-end electronics because of its sleek design. The shiny surface adds a premium touch to any product or structure, helping to create an elegant visual effect while still offering durability.

Resistance to Fading and Stains

Unlike painted or coated metals, glossy anodized aluminum by JM Aluminium does not peel or chip over time. The anodizing process bonds the protective layer directly with the aluminum, making it much more stable. It is also highly resistant to fading caused by sunlight, which is a common issue with painted finishes. This makes it an excellent choice for outdoor applications such as window frames, balcony railings, or exterior cladding. Additionally, its smooth, sealed surface resists stains and dirt, making it easy to clean and maintain with just mild soap and water.

Eco-Friendly and Sustainable Properties

Another advantage of glossy anodized aluminum is its environmental friendliness. The anodizing process is non-toxic and produces minimal waste compared to other finishing methods. Aluminum itself is a recyclable material, meaning that glossy anodized aluminum products can be reused and repurposed without losing quality. This makes it an ideal choice for sustainable building projects and eco-conscious industries. By choosing anodized aluminum, manufacturers and consumers reduce their environmental impact while still benefiting from a strong and attractive material.

Uses Across Multiple Industries

Glossy anodized aluminum is incredibly versatile, which is why it is used in a wide range of industries. In construction, it is a favorite for window frames, doors, and curtain walls because of its weather resistance and visual appeal. The automotive industry uses it for trims and decorative elements, while electronics companies use it to create sleek laptop casings, phone bodies, and audio equipment. It is also popular in signage, furniture production, and even kitchen appliances. Its combination of strength and style makes it suitable for both functional and decorative purposes.

Easy Maintenance for Lasting Shine

Maintaining glossy anodized aluminum is straightforward and hassle-free. Because of its protective layer, it does not require frequent polishing or special cleaning products. A simple wash with water and mild detergent is usually enough to keep it looking bright and clean. This low-maintenance nature makes it a practical choice for both residential and commercial use. Even after years of exposure to outdoor conditions, glossy anodized aluminum retains its shine and does not need repainting or refinishing, which helps save time and money in the long run.

Glossy anodized aluminum by Western India’s largest aluminium extrusion company, JM Aluminium represents the perfect balance between style and practicality. Its reflective finish enhances the appearance of any product, while its durable surface ensures it can withstand the challenges of daily use and harsh environments. From skyscrapers to smartphones, this material plays a vital role in modern design and manufacturing. Understanding what glossy anodized aluminum is and why it matters helps builders, designers, and consumers make informed decisions about the materials they choose. With its long-lasting performance, minimal maintenance needs, and sustainable qualities, glossy anodized aluminum continues to be a preferred choice for projects that require both elegance and durability. It is more than just a shiny surface; it is a reliable investment in quality and beauty for years to come.