The Future of Label Applicator Technology: Trends to Watch

In the fast-paced world of manufacturing, packaging, and logistics, label applicators have evolved from being simple mechanical tools to advanced, intelligent machines. They not only speed up production but also ensure consistency, precision, and compliance with industry standards.

As consumer expectations grow, government regulations tighten, and supply chains demand higher efficiency, label applicator technology is undergoing significant transformations. The next generation of machines will be smarter, more sustainable, and more versatile than ever before.

In this article, we explore the key trends shaping the future of label applicator technology and how they can help businesses stay ahead in a competitive market.

1. Automation and AI Integration

Automation has already reshaped labeling processes, but the integration of artificial intelligence (AI) is setting a new benchmark for performance.

-

Self-Calibration: Future label applicators will automatically detect label size, shape, and product dimensions, adjusting settings without human intervention.

-

Error Detection: AI-powered vision systems will identify misaligned or wrinkled labels instantly, preventing defective products from leaving the production line.

-

Predictive Maintenance: Instead of waiting for breakdowns, machines will use predictive analytics to alert operators before issues occur, reducing costly downtime.

For industries like pharmaceuticals and food packaging, where precision is critical, AI integration will ensure both compliance and efficiency.

2. IoT-Connected Label Applicators

The Internet of Things (IoT) is revolutionizing how label applicators are monitored and maintained.

With IoT-enabled systems:

-

Real-Time Monitoring: Managers can track performance, speed, and label usage from any location using cloud-based dashboards.

-

Remote Troubleshooting: Service technicians can diagnose and fix issues without being physically present.

-

Data-Driven Insights: Detailed analytics on machine usage and downtime will help companies make smarter operational decisions.

For businesses running multiple production lines or facilities, IoT connectivity means greater control and reduced production delays.

3. Sustainability and Eco-Friendly Labeling

Sustainability is no longer optional — it’s a competitive necessity. Label applicator technology is evolving to handle eco-conscious materials and reduce waste.

-

Recyclable and Biodegradable Labels: New applicators can work with thinner films and sustainable adhesives without compromising performance.

-

Linerless Label Technology: By removing backing paper entirely, this method eliminates tons of waste annually in large-scale operations.

-

Energy Efficiency: Manufacturers are designing machines with lower power consumption, making them both cost-effective and environmentally friendly.

As brands commit to greener packaging, label applicators will play a key role in achieving corporate sustainability goals.

4. High-Speed and Multi-Format Application

Consumer demand for customized packaging means companies often need to apply multiple label formats quickly.

Future trends include:

-

Quick Changeovers: Switching between label sizes and shapes without halting production.

-

Advanced Servo Motors: Allowing faster labeling without sacrificing accuracy.

-

Multi-Function Units: Capable of applying front, back, wrap-around, and top labels in one pass.

This flexibility will benefit industries like beverages, cosmetics, and e-commerce, where product variation is common.

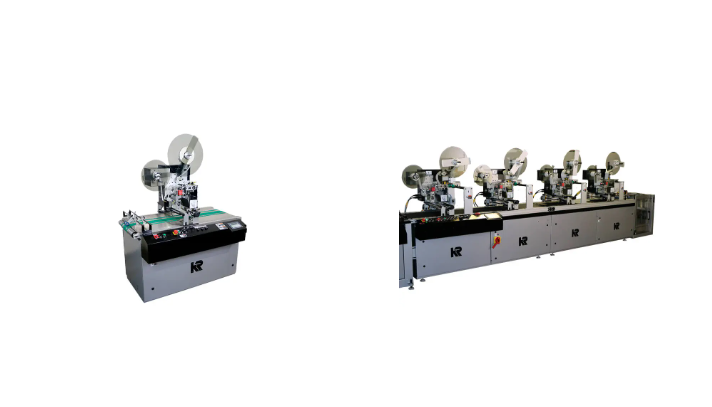

5. Compact and Modular Designs

Space is at a premium in modern production facilities. The next generation of label applicators will prioritize:

-

Smaller Footprints: Compact machines that fit into tight spaces while maintaining output capacity.

-

Modular Components: Allowing easy upgrades and integration into existing conveyor systems.

-

Portability: Lightweight designs for mobile or on-demand labeling needs.

This trend is especially relevant for small and medium-sized enterprises (SMEs) looking to scale operations without costly factory expansions.

6. Advanced Vision and Verification Systems

Labeling accuracy isn’t just about aesthetics — it’s about compliance, traceability, and brand protection.

Upcoming advancements in vision inspection technology will:

-

Verify Label Placement: Ensuring each label is perfectly aligned and free from defects.

-

Check Barcodes and Dates: Guaranteeing scannability and regulatory compliance.

-

Detect Printing Errors: Spotting missing or smudged information before products leave the factory.

These systems are particularly important for pharmaceuticals, chemicals, and food industries where mislabeling can lead to legal issues.

7. Industry-Specific Customization

One-size-fits-all solutions are fading as more businesses demand specialized label applicators tailored to their needs.

Examples include:

-

Pharmaceutical Industry: Applicators that add tamper-evident seals and serialize each package.

-

Food & Beverage Industry: Machines that apply moisture-resistant labels for chilled or frozen goods.

-

Cosmetics Industry: Precision applicators for irregular or curved containers.

Custom solutions not only improve efficiency but also strengthen brand presentation.

8. Integration with Digital Printing

The future will see more integration between label applicators and digital printing systems.

This will allow:

-

On-Demand Customization: Printing and applying unique labels for short runs or personalized products.

-

Reduced Inventory: No need to stock pre-printed labels in bulk.

-

Faster Turnaround: Eliminating delays caused by waiting for label shipments.

For industries embracing mass customization, this integration is a game changer.

Final Thoughts

The future of label applicator technology is marked by smart automation, sustainable solutions, and unparalleled flexibility. Businesses that invest in next-generation machines will benefit from:

-

Faster production speeds

-

Reduced waste and operational costs

-

Improved product presentation and compliance

As trends like AI, IoT, and eco-friendly design continue to advance, label applicators will become even more valuable in modern packaging lines.

Companies that embrace these innovations early will position themselves as industry leaders, ready to meet the demands of an evolving market while maintaining efficiency and sustainability.