PCB Fabrication Taiwan: Quality Meets Cutting-Edge Tech

In the world of modern electronics, printed circuit boards (PCBs) serve as the unsung heroes behind nearly every device. From smartphones and laptops to medical equipment and automotive systems, PCBs provide the structural foundation and electrical pathways needed for components to function seamlessly. As global demand for more powerful and compact devices continues to surge, the PCB industry finds itself at the core of innovation—and few countries have embraced this challenge like Taiwan.

Taiwan’s reputation in the global electronics industry is well-established, but what sets its PCB fabrication sector apart is the unique intersection of quality manufacturing, advanced technologies, and a highly integrated supply chain. Companies and professionals seeking reliable and forward-thinking partners often turn to PCB Fabrication Taiwan to meet their needs. Let’s take a closer look at why Taiwan is at the forefront of PCB development and what makes its manufacturing ecosystem so robust.

The Rise of PCB Fabrication in Taiwan

Taiwan’s entry into the electronics manufacturing scene began decades ago, but it was during the 1980s and 1990s that the island truly started carving a niche in PCB production. With government support, industry collaboration, and a commitment to high standards, Taiwan quickly became a global leader in PCB fabrication.

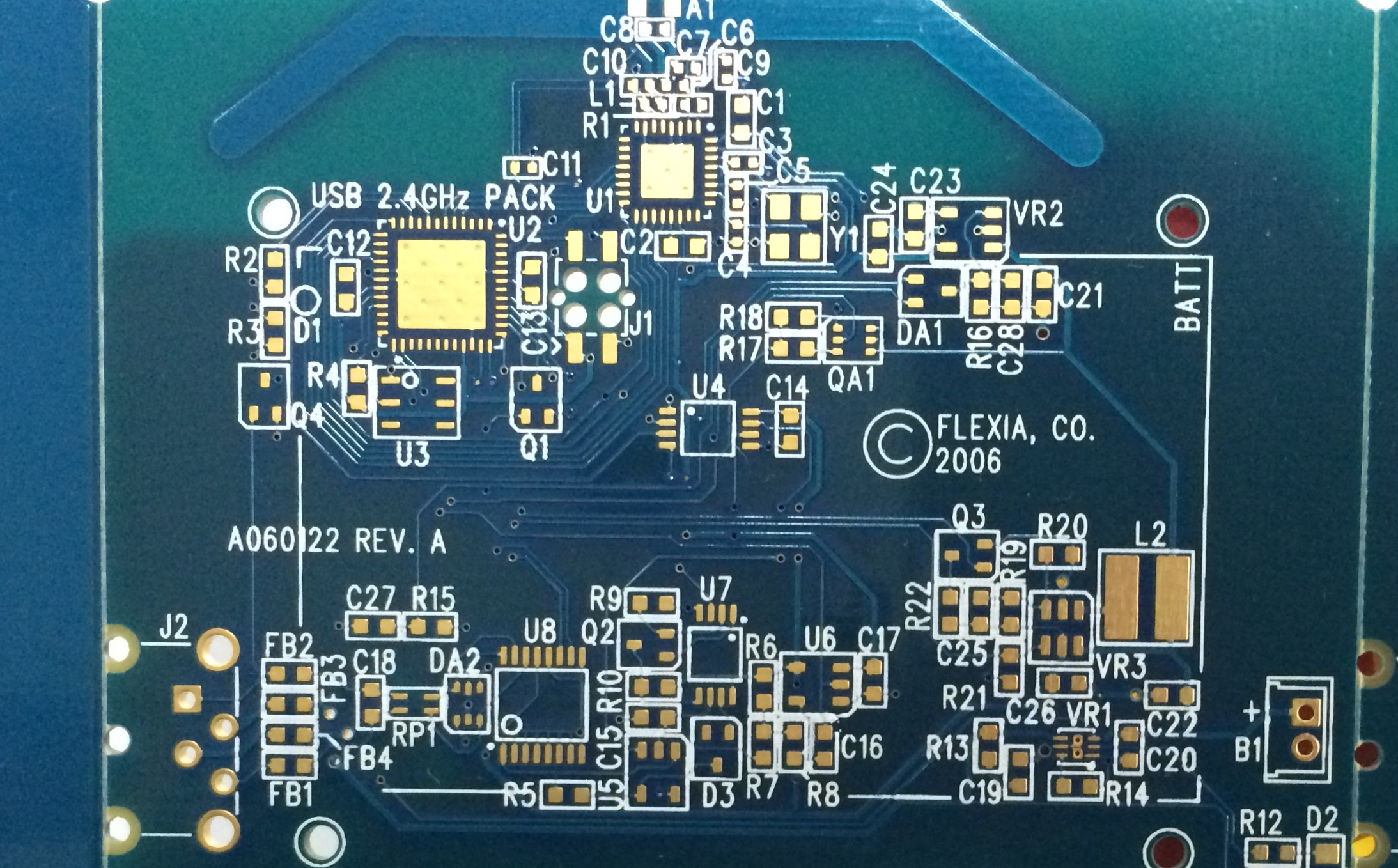

Today, Taiwan ranks among the top three PCB producers globally, boasting a vast array of manufacturers capable of producing everything from standard single-layer boards to complex multilayer and high-density interconnect (HDI) PCBs. This scalability makes Taiwan a preferred destination for industries ranging from consumer electronics to aerospace and defense.

Commitment to Quality and Precision

One of the standout characteristics of PCB Fabrication Taiwan is its uncompromising commitment to quality. Taiwanese manufacturers adhere to strict international standards, including ISO 9001, ISO 14001, IATF 16949, and UL certifications. These ensure that every board manufactured meets the requirements of performance, safety, and environmental responsibility.

Whether you’re looking to prototype a new IoT device or need volume production for automotive systems, Taiwan’s PCB makers are equipped to deliver consistent quality. Many factories implement real-time monitoring and automated optical inspection (AOI) processes to detect flaws during production, ensuring a low failure rate and high customer satisfaction.

For those interested in detailed technical processes and quality assurance practices, you can Find Out More by connecting directly with leading Taiwanese PCB firms or reviewing their published case studies.

Advanced Technologies and Innovation

While quality is a major driver, it’s Taiwan’s push toward technological innovation that truly sets it apart. The industry has embraced a range of advanced manufacturing processes, such as:

- Flexible and Rigid-Flex PCB Production: With wearables and foldable devices becoming increasingly popular, flexible PCBs are essential. Taiwanese companies have developed proprietary methods for producing these complex structures while maintaining durability.

- High-Frequency and High-Speed Materials: For applications like 5G, autonomous vehicles, and aerospace communication systems, traditional PCB materials no longer suffice. Taiwan’s manufacturers are among the early adopters of materials like PTFE and ceramic substrates that support high-speed signal transmission.

- Embedded Component Technology: By embedding passive components directly into the PCB, designers can save space and enhance performance. This requires precision engineering, something Taiwan’s fabricators excel in.

To check over here and explore specific innovations by Taiwan’s top PCB firms, many company websites feature whitepapers, videos, and client testimonials that offer a behind-the-scenes look at their R&D efforts.

Environmental Responsibility and Sustainability

As global awareness of environmental issues grows, sustainability has become a core focus in Taiwan’s PCB industry. Manufacturers are investing heavily in wastewater treatment, recycling processes, and energy-efficient equipment. Some leading PCB firms have even implemented circular economy principles, minimizing waste and reducing carbon footprints across their supply chains.

This focus on green practices not only supports environmental goals but also appeals to international partners who value sustainability as a key component of corporate responsibility.

Integrated Supply Chain and Global Reach

Another advantage of sourcing from PCB Fabrication Taiwan is the highly integrated and collaborative ecosystem. Taiwan hosts a dense cluster of suppliers, manufacturers, logistics providers, and component vendors within close proximity. This shortens lead times, enhances communication, and allows for agile responses to market demands.

In addition, Taiwanese PCB firms often have global logistics capabilities, with production sites or partners in Southeast Asia, Europe, and North America. This ensures timely delivery and reduced tariffs for international clients.

If you’re considering partnering with a PCB manufacturer for your next project, it’s wise to go right here and evaluate Taiwan-based providers who offer transparent timelines, competitive pricing, and proven track records.

Tailored Services for Diverse Industries

Taiwanese PCB manufacturers understand that different industries have vastly different needs. Whether it’s the ultra-tight tolerances required in medical electronics or the rugged durability needed for military-grade applications, Taiwan’s fabricators offer custom solutions backed by expert engineering teams.

Some services include:

- Rapid prototyping and quick-turn PCB services

- Custom multilayer board design with impedance control

- Turnkey solutions, including PCB assembly (PCBA)

- Design-for-manufacturability (DFM) consultations

These services are especially valuable for startups and small businesses, who may lack the in-house expertise to manage complex PCB projects on their own.

Final Thoughts

In an age where electronics are integral to nearly every aspect of life, the importance of reliable, high-quality PCBs cannot be overstated. Taiwan stands out as a global leader in PCB fabrication, offering a powerful combination of precision manufacturing, technological innovation, and customer-centric service.

Whether you’re launching a new product or scaling up production, PCB Fabrication Taiwan provides the capabilities and confidence needed to bring your vision to life. For deeper insights, feel free to Find Out More, check over here, or go right here to explore partnerships with Taiwan’s top PCB providers.

With its unwavering dedication to quality and a clear eye on the future, Taiwan isn’t just keeping pace—it’s leading the charge in global PCB innovation.