Machine Slide Repair Service for Precision and Reliability | Gilman Precision

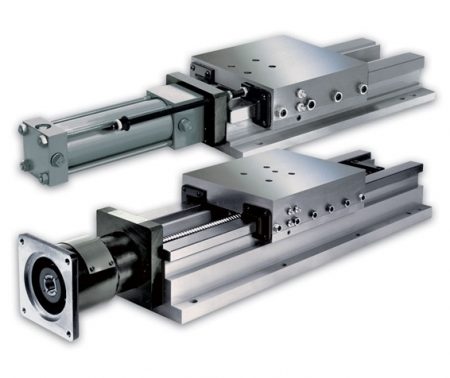

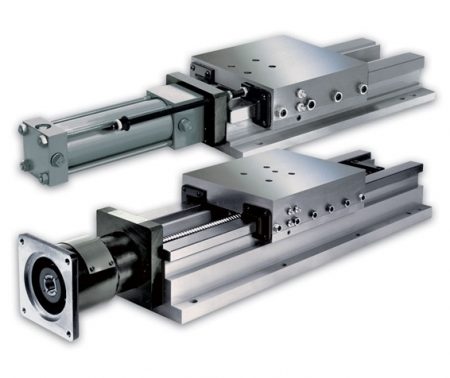

Machine slides are critical components in precision machining, providing smooth, stable, and accurate linear motion for a wide range of equipment. Over time, slides can experience wear, misalignment, or surface damage due to heavy use, improper maintenance, or harsh operating environments. Gilman Precision offers professional machine slide repair service designed to restore performance, accuracy, and longevity. By addressing slide issues promptly, manufacturers can maintain operational efficiency, reduce downtime, and protect their investment in high-value machinery.

Importance of Machine Slide Maintenance

Enhancing Accuracy and Performance

Worn or damaged machine slides can negatively affect the precision of equipment, leading to inconsistent cuts, poor surface finish, and dimensional inaccuracies. Regular repair and maintenance ensure that slides maintain their original alignment and smooth motion, preserving the quality of finished parts.

Extending Equipment Life

Prolonged use of degraded slides can place additional stress on other machine components, accelerating wear and potentially causing expensive failures. Timely repair restores optimal performance, extending the overall lifespan of the machinery.

Reducing Operational Downtime

Unexpected slide failures can halt production and disrupt workflows. Proactive repair services minimize downtime, ensuring that manufacturing operations continue without unnecessary interruptions.

Cost Savings

Repairing slides is more cost-effective than replacing entire assemblies. Gilman Precision’s services allow businesses to achieve peak performance without incurring the expense of new equipment.

Services Offered in Machine Slide Repair

Diagnostic Assessment

Every slide repair begins with a detailed inspection to identify issues such as wear, misalignment, surface damage, or component failure. This diagnostic process ensures the most effective repair approach.

Surface Restoration

Damaged slide surfaces are precision-ground or polished to restore flatness and smoothness. This process eliminates friction points and improves linear motion for consistent accuracy.

Component Replacement

Worn or damaged components such as bearings, gibs, or guide rails are replaced with high-quality parts to restore performance. All replacements are engineered to meet or exceed original equipment specifications.

Alignment and Calibration

Slides are realigned and calibrated to maintain precise motion along the intended axes. Proper alignment ensures minimal vibration, improved surface finish, and reliable operation.

Custom Solutions

Gilman Precision offers tailored repair solutions for unique slide configurations and specialized machinery, ensuring that every repair meets the specific requirements of the application.

Benefits of Choosing Gilman Precision

Expertise and Experience

With decades of experience, Gilman Precision combines technical knowledge with hands-on skills to deliver high-quality slide repair solutions. Technicians understand the nuances of different machine types and applications.

Precision Engineering

All repairs are performed using advanced equipment and precision techniques, ensuring restored slides meet exacting performance standards.

High-Quality Materials

Replacement components and repair materials are selected for durability and compatibility, ensuring long-term reliability.

Fast Turnaround

Understanding the importance of operational continuity, Gilman Precision prioritizes efficient repair processes without compromising quality, minimizing production downtime.

Comprehensive Support

Beyond repairs, Gilman Precision provides guidance on maintenance best practices, preventive measures, and monitoring strategies to keep slides operating at peak performance.

Applications Across Industries

Automotive Manufacturing

Machine slides are essential in automotive production for milling, grinding, and assembly operations. Gilman Precision repairs ensure consistent performance and precise part fabrication.

Aerospace and Defense

High-precision slides are critical for aerospace components. Properly maintained slides guarantee tight tolerances, reliability, and compliance with rigorous industry standards.

Medical Device Manufacturing

Medical equipment and instrumentation require extremely accurate machining. Slide repair services restore the precision needed for producing critical medical components.

Industrial Automation

Automated production lines rely on smooth and accurate slide motion. Repair services help maintain continuous operation and high-quality output in automated environments.

General Manufacturing

From energy and electronics to heavy machinery, all industries benefit from restored slide performance, improving operational efficiency and reducing maintenance costs.

Preventive Maintenance Tips

Regular Inspections

Frequent visual and operational inspections help detect wear or damage early, allowing for timely repairs before major issues occur.

Proper Lubrication

Maintaining appropriate lubrication reduces friction, wear, and heat buildup, extending slide life and ensuring smooth motion.

Alignment Checks

Periodic alignment verification ensures that slides remain correctly positioned, preventing uneven wear and maintaining precision.

Load Management

Operating slides within recommended load limits minimizes stress and prolongs service life.

Documentation and Monitoring

Tracking slide performance and maintenance activities helps in scheduling preventive repairs and optimizing machine reliability.

Advantages of Professional Repair

Choosing Gilman Precision for slide repair ensures that repairs are performed with precision, expertise, and attention to detail. Professional repairs restore the original performance of slides, improve operational efficiency, and prevent costly downtime. By relying on experienced technicians and advanced equipment, businesses gain confidence that their machinery will perform reliably, maintain accuracy, and continue to deliver high-quality output.

Conclusion

Machine slides are foundational components in precision machinery, and their maintenance is essential for consistent, accurate, and reliable operation. Gilman Precision’s machine slide repair services provide comprehensive solutions to restore performance, extend equipment life, and reduce operational downtime. With expertise in diagnostics, component replacement, surface restoration, alignment, and calibration, Gilman Precision ensures that every slide operates at its peak potential.

By investing in professional slide repair services, manufacturers across industries can maintain high productivity, preserve machining accuracy, and protect their equipment investments. Gilman Precision’s commitment to quality, precision, and customer satisfaction makes it a trusted partner for all machine slide repair needs, delivering solutions that enhance operational efficiency and support long-term manufacturing success.