How to Choose the Perfect Carbon Fiber Alternative for Your Project

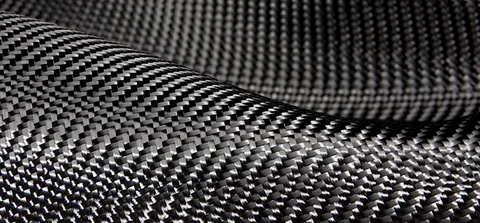

Selecting the ideal material for a project can be challenging, especially when balancing performance, cost, and sustainability. Carbon fiber is renowned for its strength, lightweight properties, and versatility, but it often comes with high costs and environmental concerns. Fortunately, modern engineering has introduced numerous carbon fiber alternatives that provide similar benefits without some of the downsides. Understanding the characteristics, applications, and trade-offs of these alternatives is key to making the right choice for your specific project.

In this guide, we’ll explore how to choose the perfect carbon fiber alternative, considering factors like material strength, durability, cost-effectiveness, and environmental impact. By the end, you’ll have a comprehensive understanding to make an informed decision that aligns with both your technical requirements and sustainability goals.

Understanding Your Project Requirements

Before exploring carbon fiber alternatives, it’s crucial to define the specific requirements of your project. Every project has different needs, whether it’s weight reduction, structural strength, flexibility, or thermal resistance. Identifying the primary goal will help narrow down suitable materials. For example, an automotive project may prioritize lightweight strength, whereas a furniture design might focus on aesthetics and sustainability. Taking the time to list your project’s priorities ensures you choose a material that excels in the areas that matter most.

Another critical consideration is the environment in which the material will be used. Factors like exposure to moisture, temperature fluctuations, and mechanical stress influence which carbon fiber alternative will perform best. Some materials offer excellent tensile strength but may degrade under UV exposure, while others provide durability in harsh environments but are less flexible. By clearly understanding the conditions your project will face, you can eliminate unsuitable options early and focus on alternatives that meet both performance and longevity expectations.

Evaluating Strength and Durability

One of the main reasons carbon fiber is preferred in high-performance applications is its exceptional strength-to-weight ratio. When selecting a carbon fiber alternative, evaluating mechanical properties such as tensile strength, compressive strength, and fatigue resistance is essential. Materials like fiberglass, aramid fibers (e.g., Kevlar), and natural fiber composites can offer impressive structural capabilities at a fraction of the cost. Each alternative has unique characteristics that may align differently with project requirements.

Durability is another crucial factor to consider. Some carbon fiber alternatives are more resistant to impact and wear, while others excel in preventing corrosion or chemical degradation. For example, fiberglass composites resist moisture and chemicals, making them ideal for marine or outdoor applications. Meanwhile, thermoplastic composites can endure repeated stress and deformation without cracking. Assessing both strength and durability ensures that the chosen material not only meets immediate needs but also maintains performance over time.

Considering Weight and Flexibility

One of the standout benefits of carbon fiber is its lightweight nature, which significantly enhances performance in applications like aerospace, automotive, and sports equipment. When searching for a carbon fiber alternative, weight is a crucial factor to balance with strength. Materials like bamboo fiber composites or high-performance plastics can provide a lightweight solution without sacrificing structural integrity. By understanding the weight requirements of your project, you can avoid materials that may add unnecessary bulk or reduce efficiency.

Flexibility is another important consideration. While some projects demand rigid materials, others require components that can bend, flex, or absorb energy without breaking. For instance, aramid fiber composites offer a combination of strength and flexibility, making them suitable for protective gear and flexible panels. Evaluating the balance between weight and flexibility in carbon fiber alternatives ensures that the material complements the design rather than limiting functionality.

Cost and Manufacturing Considerations

Budget constraints play a significant role in material selection. Carbon fiber is often expensive due to the complexity of its manufacturing process and the cost of raw materials. Fortunately, many carbon fiber alternatives offer a more cost-effective solution while still delivering comparable performance. Fiberglass, natural fiber composites, and thermoplastic materials can significantly reduce production costs, making them attractive options for both small-scale projects and large-scale manufacturing.

Manufacturing compatibility is another critical factor. Some alternatives can be processed using conventional techniques such as molding, extrusion, or 3D printing, while others require specialized equipment. Understanding the manufacturing requirements and limitations of each carbon fiber alternative helps prevent costly delays and ensures a smoother production process. By considering both cost and manufacturability, you can identify the material that provides the best value without compromising on quality or performance.

Sustainability and Environmental Impact

Environmental considerations are increasingly important when selecting materials. Traditional carbon fiber production is energy-intensive and generates waste, prompting many engineers and designers to explore greener options. Bio-based composites, recycled fibers, and natural materials like hemp or flax are emerging as eco-friendly carbon fiber alternatives. These materials reduce the environmental footprint of a project while still delivering strong, lightweight performance.

Additionally, sustainability goes beyond raw materials to include end-of-life considerations. Some carbon fiber alternatives are easier to recycle or repurpose, reducing landfill waste and promoting a circular economy. Evaluating the environmental impact of different options not only aligns with ethical and regulatory standards but can also enhance the marketability of your product. By integrating sustainability into your material selection process, you contribute to a more responsible and innovative approach to design.

Conclusion

Choosing the perfect carbon fiber alternative requires careful consideration of multiple factors, including project requirements, strength, weight, cost, and environmental impact. By understanding the specific needs of your project and evaluating each material’s performance and sustainability, you can identify the ideal alternative that balances efficiency, durability, and eco-friendliness.

With the increasing availability of high-quality carbon fiber alternatives, designers and engineers now have more options than ever to achieve outstanding performance while reducing costs and environmental impact. Whether you’re working on automotive components, sports equipment, or innovative design projects, selecting the right material is crucial to ensuring success and longevity. Taking a strategic, informed approach to material selection will help you create products that are strong, lightweight, and sustainable—without compromising on quality or functionality.