How Flexible PCB Manufacturers Drive Miniaturization

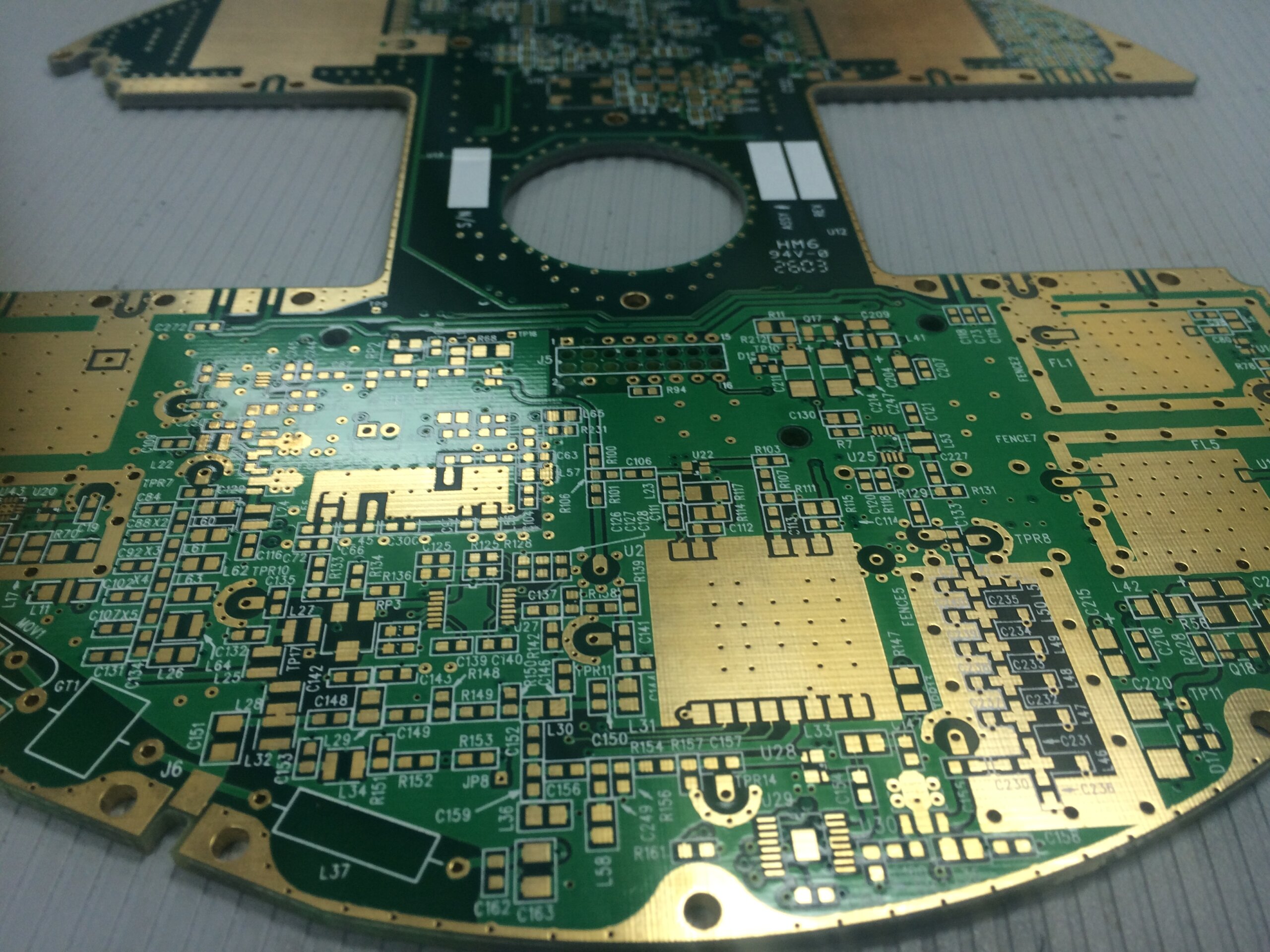

In today’s technology-driven world, the demand for smaller, lighter, and more efficient devices continues to grow. From smartphones and wearable devices to advanced medical instruments and aerospace equipment, industries are racing toward miniaturization without sacrificing performance. At the heart of this innovation lies the contribution of flexible printed circuit boards (flex PCBs). A Flexible PCB Manufacturer plays a crucial role in helping businesses meet these demands by enabling compact designs, improving reliability, and pushing the boundaries of modern electronics.

The Role of Flexible PCBs in Miniaturization

Traditional rigid PCBs, while reliable, present limitations when it comes to designing ultra-compact devices. They are bulkier, harder to mold into unique shapes, and often add unnecessary weight. Flexible PCBs solve these challenges by offering:

- Bendability and foldability: This allows electronic components to fit into tight spaces and unconventional product designs.

- Lightweight structures: Perfect for portable and wearable devices.

- Reduced interconnects: Flexible PCBs minimize connectors and solder joints, cutting down on weight and space requirements.

- Enhanced durability: They absorb vibrations and mechanical stress better than rigid boards.

By incorporating these benefits, flexible PCB technology paves the way for smaller and more efficient devices across multiple industries.

Innovations Driving the Trend

Flexible PCB manufacturers are not only meeting existing requirements but also pioneering new technologies that accelerate miniaturization. Some notable innovations include:

- High-Density Interconnect (HDI) Flex PCBs

HDI designs allow manufacturers to embed more functionality in a smaller area. This is particularly useful for devices like smartphones, where space is at a premium. - Multi-layer Flex Circuits

Instead of relying on bulky rigid boards, multi-layer flex circuits allow engineers to stack several layers while maintaining flexibility. This approach dramatically reduces device size. - Rigid-Flex Hybrid Solutions

By combining rigid and flexible layers, rigid-flex PCBs provide both stability and design versatility. They enable manufacturers to place components strategically, saving space and improving product durability. - Advanced Materials

Manufacturers now use heat-resistant, thin, and durable substrates such as polyimide films, ensuring that flexible PCBs can withstand extreme conditions without increasing bulk. - Miniaturized Components Integration

As electronic components themselves become smaller, flexible PCB manufacturers adapt their designs to accommodate chip-scale packages and microelectronic devices, further promoting miniaturization.

Industry Applications Benefiting from Miniaturization

The benefits of flexible PCBs extend across many sectors, each relying on miniaturization to meet consumer and industrial demands.

- Consumer Electronics: Smartphones, tablets, and wearables rely heavily on flexible PCBs to stay slim, lightweight, and durable.

- Medical Devices: Life-saving tools like pacemakers, hearing aids, and diagnostic equipment require ultra-compact designs enabled by flex PCB technology.

- Automotive: With electric vehicles and smart systems on the rise, flexible PCBs power advanced driver assistance systems, infotainment units, and compact control modules.

- Aerospace & Defense: Lightweight and durable PCBs are critical for satellites, drones, and military-grade equipment where every gram and inch of space counts.

Why Choose the Right Flexible PCB Manufacturer?

While many companies provide PCB solutions, selecting the right manufacturing partner can make all the difference. A reliable Flexible PCB Manufacturer not only delivers high-quality products but also ensures:

- Precision Engineering: Meeting exact design tolerances for compact electronics.

- Cutting-edge Technology: Utilizing the latest manufacturing techniques for miniaturization.

- Customization: Providing tailored solutions based on unique product requirements.

- Quality Assurance: Ensuring durability and compliance with international standards.

These factors directly impact product performance, making it essential to work with an experienced and trusted provider.

Spotlight on Pcb-Togo Electronic, Inc

One such industry leader is Pcb-Togo Electronic,Inc. With years of expertise in PCB design and manufacturing, the company has built a reputation for delivering innovative flexible PCB solutions that drive miniaturization across industries. Their state-of-the-art facilities and commitment to excellence ensure clients receive top-quality, reliable, and cost-effective products.

The company specializes in:

- High-density and multilayer flexible PCBs

- Rigid-flex hybrid designs

- Rapid prototyping and large-scale production

- Custom-tailored PCB solutions for diverse applications

By combining advanced technology with customer-focused service, Pcb-Togo Electronic, Inc continues to support businesses in achieving miniaturization without compromising functionality.

The Future of Miniaturization with Flexible PCBs

Looking ahead, the role of flexible PCB manufacturers will become even more critical. As industries transition to smarter devices and next-generation technologies such as IoT, 5G, and AI-driven hardware, flexible PCBs will be at the forefront. Trends such as transparent circuits, wearable medical patches, and ultra-thin displays highlight the future possibilities of miniaturization.

Manufacturers will also focus on sustainability by developing eco-friendly materials and processes that reduce electronic waste while still advancing miniaturization. This balance between innovation and environmental responsibility will be key in the years to come.

Final Thoughts

Miniaturization is no longer just an industry trend—it’s an expectation. From enhancing user experience in consumer electronics to enabling life-saving medical advancements, flexible PCBs have proven indispensable. By working with a trusted partner like Pcb-Togo Electronic, Inc, businesses can unlock the full potential of miniaturization, delivering products that are not only compact but also reliable and efficient.

If you’re ready to explore the possibilities of flexible PCB technology for your business, don’t hesitate to contact us. Partnering with the right manufacturer could be the key to driving your innovation forward.