In today’s fast-paced industrial world, precision and efficiency are key drivers of success. Businesses in automotive, aerospace, medical, and manufacturing industries rely heavily on cutting-edge processes to achieve flawless components with high repeatability. One of the most trusted methods for achieving this is CNC machining services. CNC, which stands for Computer Numerical Control, has transformed the way materials are cut, drilled, and shaped, offering a reliable solution for creating complex parts.

CNC machining services provide manufacturers with the ability to produce components that meet strict specifications without compromising quality. From prototyping to mass production, CNC technology ensures consistency, speed, and cost-effectiveness. In this article, we’ll explore everything you need to know about CNC machining services, including how they work, their advantages, applications across industries, and how to choose the right service provider.

What Are CNC Machining Services and How Do They Work?

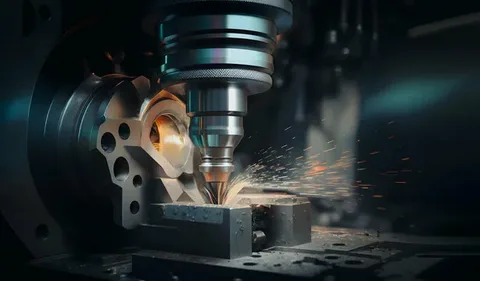

CNC machining services refer to the process of using computer-controlled machines to cut, shape, and finish materials into precise components. Unlike manual machining, where an operator directly controls the machine, CNC machining relies on digital instructions fed into the system. These instructions, often derived from CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing) software, guide the machine’s movements with extreme accuracy.

The process begins with designing a part in CAD software. The design is then converted into a code (G-code or M-code) that CNC machines can interpret. Using this code, the machine performs operations such as milling, turning, drilling, or grinding to produce the final product. CNC machining services are versatile, capable of working with a wide range of materials including metals, plastics, composites, and wood.

Key Benefits of Using CNC Machining Services

One of the primary benefits of CNC machining services is their unmatched precision. These machines can produce parts with tight tolerances, sometimes within microns, which is especially critical for industries like aerospace and medical devices. Unlike manual machining, CNC systems can replicate the same part over and over again without errors, ensuring uniformity across production batches.

Another major advantage is efficiency. CNC machining services drastically reduce production times compared to traditional methods. They allow for continuous operation with minimal supervision, enabling 24/7 production. Additionally, CNC machines minimize material waste by optimizing cutting paths, which saves costs for manufacturers. This efficiency makes CNC machining not only cost-effective but also sustainable in terms of resource utilization.

Industries That Rely on CNC Machining Services

CNC machining services are widely used across industries due to their versatility and reliability. In the aerospace industry, for example, precision is crucial when manufacturing engine components, turbine blades, or landing gear parts. CNC machining ensures that these parts meet exact specifications, contributing to flight safety and performance. Similarly, the automotive sector relies on CNC machining for producing high-performance engine parts, transmission systems, and custom accessories.

The medical industry is another area where CNC machining services play a critical role. Surgical tools, orthopedic implants, and diagnostic equipment components are often produced using CNC technology. Since these parts must adhere to strict regulatory standards, CNC machining’s precision and ability to work with biocompatible materials make it the ideal choice. Other industries that benefit include defense, electronics, and consumer goods manufacturing.

Types of CNC Machining Services Available

There are various types of CNC machining services, each designed for specific applications. CNC milling, for example, uses rotary cutting tools to remove material from a workpiece. It is ideal for creating complex shapes, holes, and slots with high accuracy. CNC turning, on the other hand, involves rotating the workpiece while cutting tools shape it, making it perfect for cylindrical components like shafts and bolts.

Other CNC machining services include drilling, grinding, and electrical discharge machining (EDM). CNC drilling produces precise holes, while CNC grinding ensures fine surface finishes. EDM is particularly useful for hard metals and complex shapes that are difficult to machine with traditional methods. With advancements in technology, multi-axis CNC machines (3-axis, 4-axis, and 5-axis) are now available, enabling manufacturers to create intricate designs with minimal setups.

How to Choose the Right CNC Machining Service Provider

Selecting the right provider for CNC machining services is crucial for ensuring quality and efficiency. The first factor to consider is the provider’s experience and expertise in handling projects similar to yours. A provider with a strong track record in your industry is more likely to understand the specific requirements and challenges you face.

It’s also important to evaluate the provider’s equipment, technology, and quality assurance processes. Modern CNC machines with multi-axis capabilities can handle complex designs more effectively. Additionally, providers that implement rigorous inspection methods, such as coordinate measuring machines (CMM), can guarantee that parts meet the required standards. Pricing, turnaround time, and customer support should also be taken into account when making your decision.

Conclusion

CNC machining services have revolutionized the manufacturing landscape by offering unmatched precision, efficiency, and versatility. From creating intricate aerospace components to producing life-saving medical devices, CNC technology has become indispensable across industries. With continuous advancements in automation and software integration, CNC machining is expected to become even more powerful and accessible in the years to come.

For businesses seeking reliable, cost-effective, and high-quality production methods, CNC machining services remain a top choice. By understanding how they work, their benefits, and how to select the right provider, companies can harness the full potential of CNC machining to stay competitive in today’s market.