Car Recycling Equipment Manufacturer – Transforming Automotive Waste into Sustainable Resources

Car Recycling Equipment Manufacturer – Driving Sustainability in the Auto Industry

The global automobile industry is one of the fastest-growing sectors, producing millions of vehicles each year. However, with this growth comes the challenge of managing end-of-life vehicles (ELVs), which contribute to massive amounts of waste and environmental hazards. Every car, after years of service, eventually reaches the point where it is no longer roadworthy. Disposing of these vehicles in landfills is neither eco-friendly nor economical. This is where the role of a Car recycling equipment manufacturer becomes vital. By producing specialized machinery, they enable efficient recycling of vehicles, helping recover valuable resources and minimize ecological damage.

In this article, we will explore the importance of car recycling, the role of a Car recycling equipment manufacturer, the types of equipment they provide, and how investing in such machinery benefits both businesses and the environment.

The Importance of Car Recycling

Car recycling is a crucial part of the global recycling industry. Automobiles are made up of metals, plastics, glass, rubber, and fluids that can either be hazardous or highly reusable. Steel and aluminum alone make up a significant portion of a vehicle’s structure. By recycling old cars, these valuable metals can be extracted, purified, and reused to manufacture new vehicles or other products.

Without proper recycling, discarded cars would lead to:

-

Soil and water pollution due to leaking oils, fuels, and coolants.

-

Increased landfill waste, which takes decades to decompose.

-

Loss of recyclable materials, which would otherwise reduce mining and raw material extraction.

A professional Car recycling equipment manufacturer develops machines that streamline the dismantling, shredding, and sorting processes, making vehicle recycling safer, faster, and more profitable.

Role of a Car Recycling Equipment Manufacturer

A Car recycling equipment manufacturer specializes in designing and delivering machinery that helps recycling companies manage the complete process of automobile recycling. From dismantling engines and tires to shredding entire car bodies, the equipment is built to maximize material recovery while ensuring eco-friendly operations.

Such manufacturers focus on three key aspects:

-

Efficiency – Ensuring maximum extraction of metals and parts with minimal energy use.

-

Safety – Reducing risks for workers by automating hazardous processes.

-

Sustainability – Supporting the circular economy by turning waste into reusable materials.

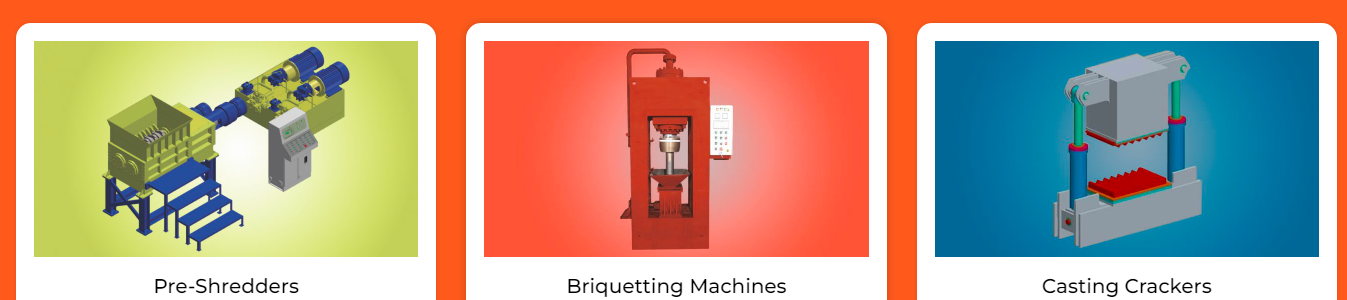

Types of Equipment Offered by a Car Recycling Equipment Manufacturer

A reputed Car recycling equipment manufacturer provides a wide range of machinery, each designed for specific stages of the recycling process. Some of the most commonly used equipment includes:

-

Car Shredders

Heavy-duty shredders break down entire vehicles into smaller pieces. This process makes it easier to separate different materials like steel, aluminum, and plastics. -

Hydraulic Balers

Balers compress scrap metal into compact bundles, making it easier to transport and store. -

Metal Separators

Advanced separators use magnets, eddy currents, and sensor-based sorting to distinguish between ferrous and non-ferrous metals. -

Dismantling Systems

Specialized equipment removes engines, transmissions, tires, and other parts efficiently without causing damage. -

Fluid Extraction Systems

These machines safely drain oils, fuel, and coolants from vehicles to prevent environmental contamination. -

Shears and Crushers

Car crushers reduce the size of vehicles, while shears cut metal into manageable pieces for further processing.

By providing this variety of machines, a Car recycling equipment manufacturer enables businesses to set up complete recycling plants.

Benefits of Working with a Car Recycling Equipment Manufacturer

1. Higher Resource Recovery

With precision-engineered machines, recyclers can recover a greater percentage of metals and reusable parts, thereby increasing profitability.

2. Cost Efficiency

Modern equipment reduces operational costs by automating labor-intensive tasks, lowering the need for manual effort.

3. Compliance with Regulations

Governments across the world are implementing strict waste management and recycling laws. Working with a Car recycling equipment manufacturer ensures compliance with these regulations.

4. Environmental Sustainability

Recycling cars minimizes landfill waste and reduces the demand for raw material mining, leading to a smaller carbon footprint.

5. Customized Solutions

Many manufacturers offer customized machinery depending on the size and needs of the recycling facility. Whether you are a small dismantler or a large-scale recycling plant, the right equipment can be tailored to your operations.

The Future of Car Recycling Equipment

The automobile industry is rapidly evolving, with electric vehicles (EVs) becoming more common. This brings new challenges, such as battery recycling. Leading Car recycling equipment manufacturers are already innovating with machines that can safely dismantle and recycle lithium-ion batteries, ensuring valuable materials like lithium, cobalt, and nickel are recovered.

Automation and AI are also shaping the future of recycling. Smart shredders, robotic dismantlers, and AI-based sorting systems are expected to revolutionize car recycling by making it faster, safer, and more precise.

How to Choose the Right Car Recycling Equipment Manufacturer

When selecting a Car recycling equipment manufacturer, consider the following factors:

-

Experience & Reputation – Choose a manufacturer with a proven track record in the recycling industry.

-

Technology & Innovation – Ensure they use advanced technologies like automation and AI for efficient recycling.

-

Customization – Look for companies that provide tailored solutions based on your facility size and capacity.

-

After-Sales Support – Reliable manufacturers offer maintenance, spare parts, and technical assistance.

-

Global Reach – If you operate internationally, partnering with a manufacturer that exports worldwide can be beneficial.

Conclusion

As the world shifts towards sustainability, car recycling has become an essential practice to reduce waste, conserve resources, and protect the environment. A reliable Car recycling equipment manufacturer plays a critical role in this process by providing advanced machinery that makes recycling efficient, safe, and profitable.

From shredders and crushers to fluid extraction systems and AI-driven sorters, these manufacturers are revolutionizing how vehicles are recycled. Partnering with the right Car recycling equipment manufacturer not only boosts your business profitability but also contributes to global sustainability efforts.