Rolex Replica vs Audemars Piguet Royal Oak Chronograph Blue Dial 41mm: A Clash of Horological Icons

In the world of high-end luxury timepieces, Rolex and Audemars Piguet (AP) stand as titans. Whether you’re a watch aficionado or a stylish enthusiast, chances are you’ve considered both brands at some point. With the growing popularity of Rolex replicas, especially high-quality superclones, many buyers are now weighing these options against iconic models like the Audemars Piguet Royal Oak Chronograph Blue Dial 41mm.

Let’s break down the key differences in style, movement, price, and value between a Rolex replica and this iconic AP model.

🔹 Design Showdown: Classic Rolex Elegance vs Royal Oak Sporty Sophistication

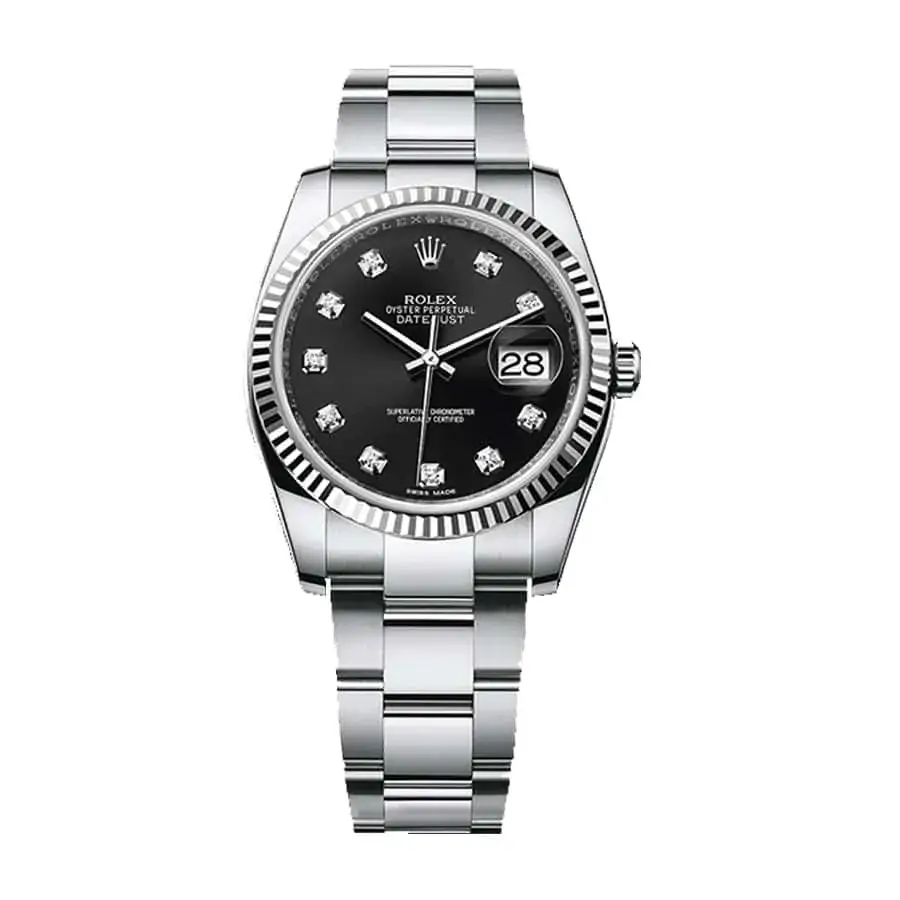

Rolex replicas (particularly of models like the Daytona or Datejust) often emulate the clean, timeless elegance of the originals. Crafted in polished stainless steel or gold-tone finishes, they typically feature minimalist dials, fluted bezels, and the iconic Oyster or Jubilee bracelet.

In contrast, the AP Royal Oak Chronograph 26331ST.OO.1220ST.01 is a design revolution. Its bold, angular 41mm stainless steel case, integrated bracelet, and the trademark “Grande Tapisserie” blue dial create a powerful wrist presence. The octagonal bezel with exposed screws is instantly recognizable—even across the room.

Winner: Audemars Piguet, for its avant-garde and masculine design, but Rolex replica holds its own with versatility and subtle class.

🔹 Movement & Mechanism: Swiss Replica Precision vs Haute Horlogerie

Top-tier Rolex replicas now come equipped with automatic Miyota or Seagull movements, and some superclone versions even offer decorated rotor plates mimicking genuine Rolex calibers. These movements are often accurate and reliable for daily use—but they lack the refined precision and finishing of authentic Swiss watches.

On the other hand, the AP Royal Oak Chronograph Blue Dial houses the Caliber 2385, a self-winding mechanical movement with a 40-hour power reserve. It’s known for high accuracy and elegant chronograph functionality.

Winner: Audemars Piguet, no contest—authentic mechanical artistry easily outpaces even the best replica movements.

🔹 Craftsmanship and Materials

Replica Rolex watches vary by grade, with AAA Swiss replicas using solid 904L or 316L stainless steel, sapphire crystal, and ceramic bezels. Many also mimic genuine weight and feel, but close inspection often reveals slightly less refined detailing in the dial printing, lume, or bracelet finishing.

AP’s Royal Oak 26331ST is crafted from premium stainless steel, with expert brushing and polishing throughout the case and bracelet. The layered blue dial with subdials and polished markers is a masterclass in finishing and layout.

Winner: Audemars Piguet—but the best Rolex replicas come surprisingly close for the price.

🔹 Features & Functionality

Rolex Replica Features:

- Date display (often functional)

- Automatic or quartz movement

- Screw-down crown (on some models)

- Water resistance (to a limited degree)

- Durable sapphire or mineral glass

AP Royal Oak Chronograph Features:

- Chronograph with subdials at 3, 6, and 9 o’clock

- Date display at 4:30 position

- Transparent caseback

- 40-hour power reserve

- Water-resistant to 50 meters

If you value chronograph complications and high-end finishing, AP is the clear choice. But if you’re after a simpler, reliable everyday timepiece at a fraction of the cost, a high-end Rolex replica delivers.

🔹 On-Wrist Feel & Style Impact

Wearing a Rolex replica can feel classy and elegant, especially models with fluted bezels or two-tone finishes. They’re perfect for business settings, weddings, and casual luxury.

But the AP Royal Oak Chronograph Blue Dial 41mm? That’s a bold statement. It has a sport-luxury presence few watches can match, thanks to its strong design lines and premium finishing. It’s not just a watch—it’s a status symbol.

Winner: Audemars Piguet, for standout design—but Rolex replica takes the win for everyday wearability and discretion.

🔹 Price Comparison: Budget vs Investment

- Rolex Replica (Superclone): $200 – $600

- Audemars Piguet 26331ST.OO.1220ST.01: ~$35,000 – $45,000 (retail or pre-owned)

That’s a massive price gap. For many enthusiasts, a Rolex replica allows them to enjoy the feel of a luxury watch without the high financial risk. Meanwhile, the AP is a collector’s piece—a true luxury investment.

Winner: Rolex replica, if value-for-money and style are your priorities.

🔹 Social Perception: Replica Risks vs Real AP Prestige

Wearing a Rolex replica might go unnoticed by most people. However, for seasoned watch enthusiasts, there’s always the risk of being called out. That said, a well-crafted superclone can pass for real even under moderate scrutiny.

With an AP Royal Oak Chronograph, there’s no question. It commands respect. People who know watches will instantly recognize the piece and associate it with wealth, taste, and exclusivity.

Winner: Audemars Piguet, no competition.

🔹 Final Verdict: Which Watch Wins?

| Feature | Winner |

| Design & Aesthetics | Audemars Piguet |

| Movement & Functionality | Audemars Piguet |

| Material Quality | Audemars Piguet |

| Price & Value | Rolex Replica |

| Everyday Wearability | Rolex Replica |

| Wrist Presence | Audemars Piguet |

| Social Impact | Audemars Piguet |

🏁 Conclusion: Choose Your Timepiece Wisely

If you’re looking for affordable luxury and the classic Rolex experience, a premium replica can offer incredible value and style. It’s a smart choice for everyday wearers who want elegance without the risk.

But if you’re after unmatched craftsmanship, mechanical prestige, and a bold design statement, the Audemars Piguet Royal Oak Chronograph Blue Dial is in a league of its own.