From Rockets to X-Rays: The Diverse Uses of Tungsten Sheets

From Rockets to X-Rays: The Diverse Uses of Tungsten Sheets

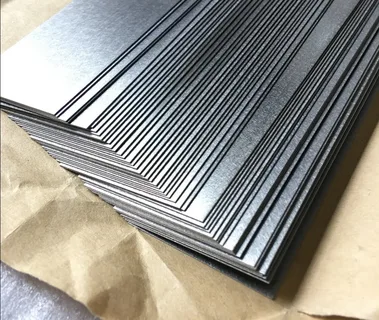

In the world of engineering and technology, certain materials stand out because they can do what most others cannot. One such material is Tungsten Sheets, which are valued for their incredible strength, durability, and ability to withstand extreme conditions. From rockets soaring into space to medical machines protecting patients during X-rays, tungsten sheets play a critical role in many industries where performance and reliability are essential.

This blog explores the remarkable properties of tungsten sheets, their diverse uses, and why they remain an irreplaceable material for advanced applications.

What Are Tungsten Sheets?

Tungsten is a rare metal known for having the highest melting point of all pure metals, at an impressive 3,422°C. It is also extremely dense about 1.7 times denser than lead. When tungsten is processed into flat, thin plates, we get Tungsten Sheets, which retain all of tungsten’s unique properties while becoming easier to shape and apply in various fields.

Unlike many metals that weaken under heat or pressure, tungsten sheets maintain their strength and form. This makes them the preferred choice for industries where performance under extreme environments is crucial.

Key Properties of Tungsten Sheets

The growing use of Tungsten Sheets can be credited to their unique physical and mechanical characteristics.

-

Extreme Heat Resistance: Tungsten sheets can withstand temperatures where most metals would melt or deform.

-

High Density: Their density makes them highly effective for radiation shielding, surpassing even lead.

-

Strength at High Temperatures: Unlike many alloys, tungsten remains strong even when heated to red-hot conditions.

-

Corrosion Resistance: Tungsten resists chemical wear and corrosion, ensuring durability in harsh environments.

-

Electrical and Thermal Conductivity: It conducts electricity and heat effectively, making it suitable for electronics and energy systems.

-

Machinability: With the right techniques, tungsten sheets can be machined into complex, precision parts.

These qualities make tungsten sheets a versatile choice across diverse industries.

Applications of Tungsten Sheets

1. Aerospace and Rocket Engineering

In aerospace, reliability can mean the difference between mission success and failure. Tungsten Sheets are used in rocket nozzles, heat shields, and counterweights because they can endure extreme heat and stress during space launches. Their density also makes them useful for balance and stability in aircraft and spacecraft.

2. Medical X-Ray and Radiation Shielding

Safety is critical in medical imaging, and tungsten sheets provide excellent protection against harmful radiation. Unlike lead, which is traditionally used for shielding, tungsten is non-toxic and offers higher density, allowing thinner sheets to block the same or greater levels of radiation. This makes Tungsten Sheets ideal for X-ray machines, CT scanners, and protective barriers in hospitals and laboratories.

3. Electronics and Semiconductors

Tungsten’s thermal and electrical conductivity makes it indispensable in electronics. Tungsten Sheets are used in semiconductors, heat sinks, and components of vacuum furnaces. They help manage heat efficiently, ensuring devices operate reliably even under heavy loads.

4. Industrial and Manufacturing Applications

In high-temperature furnaces and molds, tungsten sheets provide exceptional durability. They are also used in tooling and machining processes where ordinary metals would quickly wear out. Their resistance to wear and corrosion allows for longer tool life and reduced downtime in manufacturing plants.

5. Defense and Military Applications

Tungsten’s strength and density make it invaluable for defense. Tungsten Sheets are used in armor plating, kinetic energy penetrators, and other military hardware designed to withstand high impact. They provide protection and performance without compromising mobility or efficiency.

6. Energy and Nuclear Industry

In nuclear power plants and research facilities, tungsten sheets serve as effective radiation shielding and high-temperature components. They help protect workers and equipment while ensuring smooth operation in environments exposed to radiation and heat.

7. Emerging Technologies

As industries evolve, new applications of tungsten sheets continue to emerge. In renewable energy, for example, tungsten is being explored for use in solar power systems and advanced battery technologies. Its unique combination of properties makes it a strong candidate for the technologies of tomorrow.

Why Tungsten Sheets Are Preferred

While metals like steel, titanium, and lead are widely used, Tungsten Sheets bring together qualities that make them unmatched in specific fields. For example:

-

Compared to Steel: Tungsten is far more heat-resistant and dense.

-

Compared to Lead: Tungsten provides superior radiation shielding with less thickness and without toxicity concerns.

-

Compared to Titanium: Tungsten maintains strength at much higher temperatures.

This combination of advantages makes tungsten sheets the top choice when industries demand materials that can survive and perform under extreme conditions.

The Future of Tungsten Sheets

As technology advances, the demand for Tungsten Sheets is expected to grow significantly. Space exploration, advanced medical imaging, renewable energy, and nuclear research are all areas where tungsten’s properties are proving invaluable. Efforts are also underway to make tungsten more cost-effective and easier to process, which will broaden its use across industries.

With global industries focusing on efficiency, sustainability, and safety, tungsten sheets will continue to play a central role in solving engineering challenges.

Conclusion

From the roar of rockets breaking through the atmosphere to the quiet hum of X-ray machines protecting patient health, Tungsten Sheets demonstrate their versatility and importance every day. Their unmatched strength, density, and ability to withstand extreme conditions make them an essential material in aerospace, medicine, defense, and beyond.

As we look toward the future of technology, tungsten sheets will remain at the forefront of innovation, enabling industries to reach new heights while ensuring safety and precision. Truly, from rockets to X-rays, tungsten sheets are shaping the way forward.