Sound management is often overlooked in both residential and commercial buildings. While insulation is usually associated with energy efficiency, it also plays a significant role in reducing noise transfer between rooms or from outside sources. Open-cell spray foam insulation has become a preferred choice for sound attenuation because of its unique structure and performance characteristics. This article explores the technical aspects of open-cell spray foam, its effectiveness in controlling sound, and practical considerations for property owners.

How Open-Cell Spray Foam Functions as a Sound Barrier

Open-cell spray foam reduces sound transfer by absorbing airborne noise and disrupting sound wave movement. Its porous cellular structure makes it less rigid than closed-cell foam, allowing it to absorb vibrations and prevent echo.

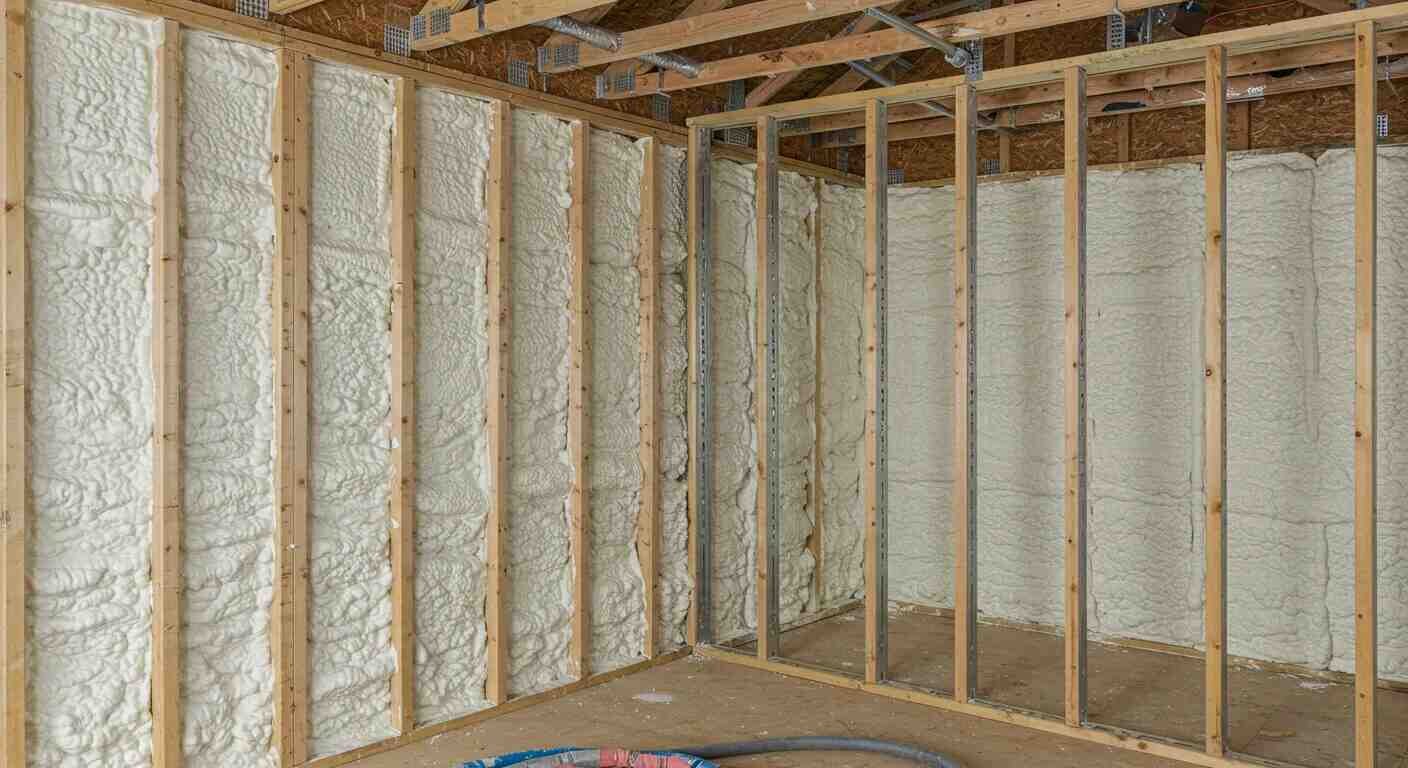

The foam is sprayed into cavities, where it expands and fills gaps, creating a seamless layer that limits pathways for sound to travel. Unlike traditional insulation batts, spray foam bonds directly to framing, which reduces flanking paths where noise can bypass insulation materials.

Porosity and Acoustic Absorption

The open-cell design means air can pass through the foam more easily, which helps trap and dissipate sound waves. This quality gives it an advantage for reducing mid- and high-frequency noise such as voices, televisions, or office activity.

Impact on Airborne Noise Transmission

Open-cell spray foam excels at reducing airborne sound transmission. Airborne noise travels through gaps and cavities, but foam seals cracks and joints, making it more difficult for sound to move between rooms.

Comparing Open-Cell Spray Foam with Alternative Insulation Materials

Different insulation materials have varying impacts on sound control. Property owners often compare fiberglass, mineral wool, and closed-cell spray foam with open-cell options.

Open-Cell vs. Closed-Cell Foam

- Open-cell spray foam: Flexible, lightweight, better acoustic absorption, less dense.

- Closed-cell spray foam: Higher density, excellent thermal resistance, limited sound absorption.

Fiberglass and Mineral Wool Comparisons

- Fiberglass batts: Widely available, moderate acoustic performance, prone to gaps during installation.

- Mineral wool: Dense and strong sound absorption, but lacks the seamless air seal that spray foam provides.

| Insulation Type | Sound Absorption | Air Sealing Ability | Moisture Resistance | Density |

|---|---|---|---|---|

| Open-cell spray foam | High | Excellent | Moderate | Low |

| Closed-cell spray foam | Moderate | Excellent | High | High |

| Fiberglass | Moderate | Low | Low | Low |

| Mineral wool | High | Low | High | Medium |

Applications of Open-Cell Spray Foam for Sound Attenuation

Noise problems vary across property types. Open-cell spray foam adapts to different scenarios where sound reduction is required.

Residential Buildings

In homes, open-cell spray foam is commonly used in:

- Interior walls to reduce room-to-room noise

- Between floors in multi-level houses

- Around mechanical rooms for quieter living spaces

Commercial Properties

In offices, schools, and retail environments, sound attenuation improves productivity and privacy. Spray foam helps in:

- Partition walls between offices

- Conference rooms for speech privacy

- Multi-use commercial units to control cross-space noise

Mixed-Use and Multi-Family Developments

Noise complaints are frequent in apartments and mixed-use developments. Open-cell spray foam can reduce disturbances from shared walls, corridors, and outdoor noise infiltration.

Technical Considerations When Using Open-Cell Spray Foam for Acoustics

Performance depends on correct installation and understanding the limitations of the material.

Placement and Thickness

Sound reduction increases with thickness. Walls, ceilings, and floor cavities benefit most when filled completely to block pathways for airborne noise.

Moisture and Environmental Factors

Open-cell foam is permeable to vapor. While this supports indoor air regulation, it requires additional moisture management in high-humidity environments. Vapor barriers or hybrid solutions may be necessary.

Compliance with Building Standards

Most acoustic ratings reference the Sound Transmission Class (STC). Open-cell spray foam can significantly improve STC ratings when combined with proper wall assemblies. Consulting building codes ensures compliance in both residential and commercial projects.

Advantages of Open-Cell Spray Foam for Noise Control

Open-cell spray foam provides multiple advantages beyond standard insulation.

Continuous Air Seal

By filling gaps and cracks, the foam reduces both sound and drafts, making the interior environment more consistent.

Lightweight and Flexible

Its lightweight structure allows it to absorb vibrations rather than transfer them, creating a more effective sound barrier.

Cost-to-Performance Balance

Compared with specialty acoustic panels, open-cell spray foam provides both insulation and sound attenuation, delivering dual benefits in one installation.

Limitations to Consider

Although effective, open-cell spray foam has limits.

Not a Complete Soundproofing Solution

It significantly reduces airborne sound but is less effective against low-frequency noises such as heavy machinery or subwoofers. Combining foam with resilient channels or double-drywall assemblies may be necessary for demanding acoustic needs.

Moisture Vulnerability

Since it is vapor-permeable, additional design steps are needed to prevent moisture intrusion, especially in below-grade or exterior-facing assemblies.

Conclusion

Open-cell spray foam offers superior sound attenuation compared to many traditional insulation methods. Its porous structure absorbs airborne noise, while its ability to expand and seal cavities prevents sound leakage. This combination makes it valuable in both residential and commercial settings where acoustic comfort matters.

Although not a complete soundproofing system, it provides substantial reductions in mid- and high-frequency noise. Property owners can improve results by integrating open-cell spray foam with other acoustic design methods. Working with an experienced spray foam insulation contractor ensures careful installation, appropriate placement, and compliance with building codes so the material performs at its best.

FAQs

Does open-cell spray foam reduce noise between floors?

Yes. When applied in floor cavities, open-cell spray foam reduces airborne noise such as conversation, music, or television between levels. For impact noise like footsteps, additional sound-damping materials are recommended.

How does open-cell spray foam affect STC ratings?

Open-cell spray foam increases STC ratings by absorbing airborne sound and sealing air gaps. Wall assemblies with open-cell insulation generally achieve higher ratings than those with fiberglass or no insulation.

Can open-cell spray foam be combined with other soundproofing methods?

Yes. Combining spray foam with resilient channels, double layers of drywall, or acoustic panels enhances performance and addresses both airborne and impact noise.

Is open-cell spray foam suitable for exterior walls in noisy urban areas?

It helps reduce traffic and outdoor noise but should be installed with proper moisture control layers. In high-exposure environments, pairing with closed-cell foam or hybrid systems may improve durability.

What frequency ranges does open-cell spray foam handle best?

Open-cell foam performs best with mid- and high-frequency sounds such as speech, office noise, and household activities. Low-frequency vibrations may require supplemental soundproofing strategies.

Author: With over two decades of hands-on experience, Robert Lamothe, owner and lead installer of Lamothe Insulation, brings unparalleled expertise in spray foam insulation, carpentry, and building science. Since 2002, he has earned a reputation for precision, quality craftsmanship, and delivering energy-efficient solutions that stand the test of time. Lamothe Insulation is a family-owned and family-operated business, and Robert also owns the Goddard School of Auburn, an early childhood education school.

Reviewer: Ethan Taylor has 8 years of experience in spray foam insulation. He reviewed this content and suggested ways to simplify business outreach while keeping trust and professionalism intact.