Diesel DEF Tanks: How FRP Material Choice Affects Storage Quality and Longevity

Storing Diesel Exhaust Fluid (DEF) properly involves more than just selecting a tank—it’s about choosing the right material to preserve its integrity. DEF is sensitive to contamination and temperature fluctuations, so the selection of storage material can directly impact its effectiveness, shelf life, and compliance with industry standards.

Let’s evaluate the role FRP material plays in the performance of a diesel DEF tank, particularly when compared to traditional options such as stainless steel and polyethylene. Let’s break it down.

Why Storage Material Matters for DEF Quality

DEF is a urea-based solution, made from high-purity urea and deionized water. It’s highly sensitive to contaminants, temperature changes, and certain materials. Any breakdown in chemical balance can lead to ineffective emissions treatment or even equipment failure.

Storage materials directly impact:

- DEF purity

- Shelf life and chemical stability

- Internal temperature control

- Compliance with handling standards

An appropriate storage tank prevents contamination, reduces evaporation, and minimizes the risk of material leaching—three key factors in maintaining DEF quality.

Comparing FRP, Stainless Steel, and Polyethylene DEF Tanks

When evaluating materials for diesel fuel storage, the focus often narrows to three common choices: FRP, stainless steel, and polyethylene. Each material offers specific advantages and trade-offs depending on application demands.

1. FRP (Fiberglass Reinforced Plastic)

FRP tanks are made by combining fiberglass with chemical-resistant resins, offering a customizable and durable option for DEF.

- Non-reactive interior surfaces protect against chemical breakdown.

- It can be tailored with features such as UV protection, thermal insulation, and structural reinforcements.

- Ideal for larger volumes and outdoor industrial settings.

FRP’s versatility in manufacturing makes it a preferred solution for industries requiring long-term, contaminant-free DEF storage.

2. Stainless Steel

Stainless steel is known for its durability and strength. It’s corrosion-resistant and widely used in food-grade and chemical storage. However, in the context of DEF:

- Trace metals may react with urea, compromising DEF purity.

- Higher fabrication and installation costs may present a financial barrier.

- Heat conductivity can lead to temperature fluctuations without the use of added insulation.

2. Polyethylene (HDPE)

High-density polyethylene tanks are lightweight and economical, making them a common choice for smaller installations.

- It may permit vapor diffusion or absorb odours over time.

- Prone to UV degradation without protective coatings.

- Typically offers limited structural strength for industrial-scale applications.

The Impact of Corrosion and Contamination on Diesel Fuel Storage Tanks

Contaminants such as rust, dust, or chemical residue can significantly alter the quality of DEF. Even minor exposure to metal ions from the tank walls can accelerate the degradation of urea. When this happens, it affects the Selective Catalytic Reduction (SCR) systems used in diesel engines to reduce NOx emissions.

Contaminated DEF may lead to the following:

- Emission system errors.

- Costly downtime and repairs.

- Non-compliance with environmental regulations.

Corrosion resistance is vital in a diesel fuel tank, especially when storing DEF in high-humidity or temperature-variable environments. FRP offers a long-term solution with its corrosion-inert surface, reducing both maintenance and contamination risks.

How FRP Material Selection Affects DEF Shelf Life and Compliance

DEF has a typical shelf life of 12 months, but this can vary depending on temperature, light exposure, and the type of tank material. Choosing FRP tanks can extend shelf life by mitigating these risks.

Benefits of FRP in DEF Storage:

- Stable Temperature Control: Optional insulation reduces fluctuation, preventing crystallization or urea breakdown.

- UV-Resistant Coatings: Prevent light-induced chemical reactions.

- Non-porous Interior Linings: Eliminate surface absorption and bacterial growth.

- Custom Geometry Options: Flat-bottom, slope-bottom, and double-wall configurations help manage residue buildup and support ease of cleaning.

FRP can also be engineered to meet regulatory guidelines for urea-based fluids, giving operators peace of mind regarding environmental and mechanical compliance.

Applications Across Industries That Depend on Diesel Fuel Storage

A wide range of industries depend on DEF for their fleet and equipment operations. Common ones include:

- Transportation and logistics: For commercial fleets requiring consistent DEF supply to meet emission standards.

- Agriculture and food processing: Used in tractors, harvesters, and other diesel-powered equipment.

- Power generation: Backup generators and equipment may use DEF to reduce NOx emissions.

- Municipal and public works: Service vehicles, refuse trucks, and snow plows require DEF throughout the year.

Each of these sectors requires tanks that can support diesel fuel storage with minimal downtime, maintenance, and risk of contamination. Temperature-sensitive materials can be safely stored in large volumes using the dependable storage solution of FRP tanks.

Guaranteeing DEF Purity with the Right Diesel Storage Tank

Quality, compliance, and consistency begin with the right tank design. As DEF becomes a standard requirement across diesel applications, selecting the correct diesel DEF tank remains a key part of operational planning.

FRP tanks offer long-term value through material integrity, chemical compatibility, and custom engineering, which support safer storage conditions and reduced waste. They help reduce the risks associated with temperature variation, metal corrosion, and surface contamination.

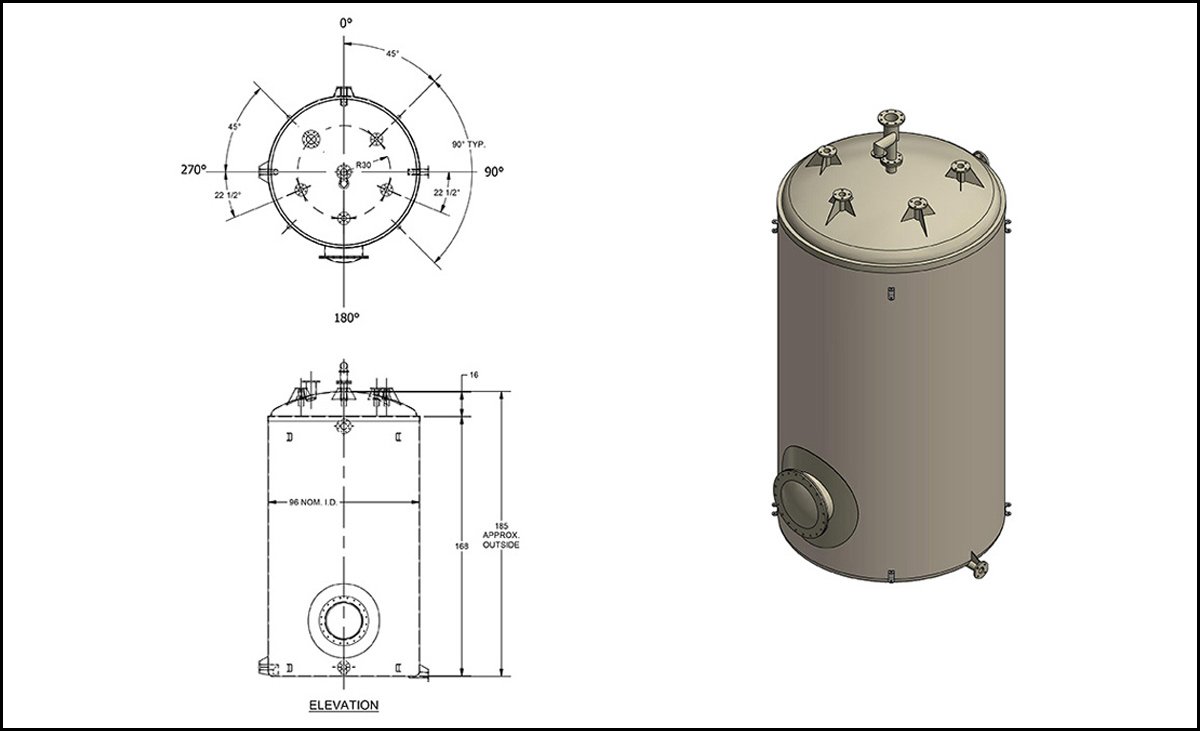

Belding Tank Technologies offers a range of fiberglass tanks, including flat-bottom designs and sloped-bottom options for improved drainage. Whether your priority is longevity, compliance, or space optimization, our custom solutions are tailored to fit your site’s requirements and service needs.

Contact Belding Tank Technologies today to discuss your DEF storage needs and learn how the right diesel storage tank can support purity, performance, and long-term reliability.