Enhance Soil Stabilization Projects Using Quality HDPE Geomembrane

Overview

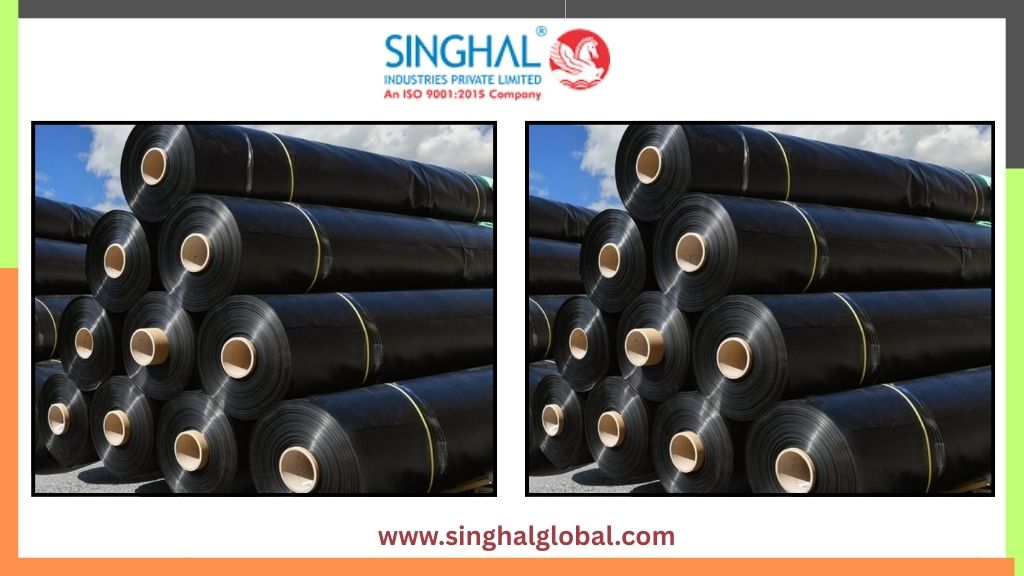

In order to maintain land’s strength, continuity, and protection from corrosion and pollution, soil stabilization has surfaced as a pivotal prerequisite for contemporary environmental and infrastructural enterprise. HDPE geomembrane liners are getting the go- to option for masterminds, contractors, and design inventors in India and throughout the world in order to insure long- lasting stability. These liners are essential for large- scale systems since they not only give a defensive hedge but also have remarkable resistance to chemicals, UV shafts, and water seepage.

Due to the benefits of continuity, cost effectiveness, and environmental safety, the operation of HDPE geomembrane liner in India has significantly increased in recent times. The need for ultraexpensive liners is only going to increase, whether it’s for mining operations, water budgets, irrigation ponds, or tips. Still, because harmonious product quality has a direct influence on design performance, choosing secure HDPE geomembrane liner manufacturers has come just as pivotal as choosing the material itself.

This essay will examine the critical part that Indian HDPE geomembrane manufacturers are playing in soil stabilization enterprise and the reasons why high- quality geomembranes are essential to sustainable development.

HDPE Geomembrane’s Function in Soil Stabilization

buttressing or altering the soil to ameliorate its structural performance is a common step in soil stabilization. Conventional ways, including the use of cement or lime, have downsides, particularly in places where humidity operation is pivotal. HDPE geomembranes give a better option in this situation. These liners boost cargo- bearing capacity, drop soil corrosion, and stop water penetration by performing as impermeable walls.

Reliable soil subcaste separation is made possible by high- quality geomembranes, which also cover the foundation from adulterants, chemicals, and humidity. For illustration, to increase pavement life, geomembrane liners are frequently used below the foundation subcaste in trace structure systems. In a analogous tone, they support soil stability and water effectiveness in agrarian operations by precluding seepage from irrigation ponds.

HDPE liners are now a dependence of stabilizing ways due to their expansive use, giving design inventors the assurance they need to attack delicate terrain and harsh rainfall conditions.

India’s Growing Need for HDPE Geomembrane Liners

The need for slice- edge soil stabilization accoutrements has increased due to India’s quick structure development. Because of its shown effectiveness, HDPE geomembrane liners are being used more and more in Indian trace, road, mining, agrarian, and artificial Sheet operation systems. HDPE liner provides long- term protection without the need for regular conservation, saving design possessors both time and plutocrat.

likewise, stakeholders have been impelled to embraceeco-friendly styles as a result of growing environmental knowledge. Because they cover groundwater from pollution and maintain soil health, geomembranes are important in this situation. The need for secure liners has increased in all Indian countries as a result of the perpetration of stronger environmental rules.

The request has grown significantly as a result of this demand, with numerous HDPE geomembrane liner manufacturers coming in to meet the colorful design requirements.

The Significance of Quality in HDPE Geomembrane Liners

Although geomembrane liners are plainly popular, design success is substantially dependent on their quality. Long- term structural problems, seepage, or environmental pitfalls may affect from inferior liners, despite their original evident cost- effectiveness.

Superior liners give harmonious consistence, outstanding tensile strength, and adaptability against breaking due to environmental stress. Extreme temperature changes and high cargo circumstances do not affect their responsibility. They’re essential for soil stabilization sweats because of their decades-long impermeability.

design possessors may be confident they will gain liners that are supported by specialized know- style and fulfill transnational quality conditions by opting estimable HDPE geomembrane manufacturers in India. estimable manufacturers make investments in slice- edge manufacturing ways and exacting testing procedures to insure dependable product performance.

India’s HDPE Geomembrane Manufacturers’ donation

In order to satisfy the rising demand both domestically and abroad, original manufacturers are fleetly enforcing global stylish practices. Beyond only producing HDPE geomembrane, Indian manufacturers also laboriously support sustainable practices, design-specific customisation, and technology developments.

Also, manufacturers work with design inventors and contractors to give specialized backing and installation support. Also, by furnishing reasonable price without immolating quality, Indian manufacturers have established a strong request position and are now major exporters of HDPE geomembranes encyclopedically.

HDPE Geomembrane operations in Soil Stabilization enterprise

Because of its rigidity, geomembrane liners are used in numerous different soil stabilizing operations. They stop leachate from contaminating the groundwater and soil in tip systems. They border ponds and conduits in Agriculture to help seepage and save near land. They’re essential to mining operations because they keep dangerous accoutrements out of the earth by securing trailing ponds.

HDPE liners are constantly used in civic structure systems for drainage, corrosion control, and dam stabilization. Geomembranes serve as a guard in each of these operations, conserving the continuity and strength of soil structures throughout time.

Unborn Prospects for HDPE Geomembrane- Grounded Soil Stabilization

The significance of geomembranes is anticipated to grow as long as India and the rest of the globe keep making investments in robust structure. Better protection will be handed at lower prices because to advancements in manufacturing ways and material design that will ameliorate liner performance indeed further. Soil stabilization systems will be more long- continuing and sustainable when geomembranes are incorporated with contemporary engineering ways.

Working with estimable HDPE geomembrane liner manufacturers that can give not just accoutrements but also results customized to specific design issues is the way of the future for design possessors. The worldwide structure and environmental protection conditioning would profit greatly from the sustained growth of HDPE geomembrane manufacturers in India.

In conclusion

For long- continuing and environmentally salutary results, the use of HDPE geomembrane liners in soil stabilization systems is now needed rather than a choice. They element of contemporary construction because of their capacity to save soil, stopseepage, and repel stress. The business is anticipated to develop steadily since India is a major supplier and manufacturer of these liners.

Singhal Industries Private Limited is one of the most estimable brands in this assiduity for stakeholders looking for unexampled quality, responsibility, and trusted experience. They’ve been a major mate in soil stabilization systems across India and abroad thanks to their fidelity to quality.

FAQs

Q1. Who is the largest supplier of HDPE Geomembrane?

Offering ultraexpensive liners across India, Singhal Industries Private Limited is honored as one of the biggest suppliers of HDPE Geomembrane.

Q2. Who is the largest exporter of HDPE Geomembrane?

The Singhal Industries Private Limited is a top exporter of HDPE Geomembrane, offering reliable goods to global commerce.

Q3. Who is the largest manufacturers of HDPE Geomembrane?

One of the biggest manufacturers of HDPE Geomembrane in India, Singhal Industries Private Limited is famed for its responsibility and high norms.

Q4. How can HDPE geomembrane help stabilize soil?

HDPE geomembrane is used to make impermeable walls that ameliorate cargo- bearing capacity, guard soil structures, and stop seepage.

Q5. What makes HDPE geomembrane superior to conventional ways for stabilizing soil?

In discrepancy to traditional ways like cement stabilization, it provides minimum conservation, chemical resistance, and long- lasting impermeability.

Q6. In India, where are HDPE geomembrane liners frequently used?

In India, they’re considerably used in road structure, budgets, conduits, mining systems, tips, and Agriculture.

Q7. What’s the lifetime of an HDPE geomembrane liner?

An HDPE geomembrane liner may last for decades in a variety of settings with correct installation and high- quality product.

Q8. What factors need to be taken into account when choosing a manufacturer of HDPE geomembrane liners?

Product quality, adherence to global norms, installation instructions, andpost-purchase backing are some of the variables.

Q9. Are HDPE geomembrane liners safe for the terrain?

Indeed, they’re ecologically sustainable because they save groundwater, reduce soil corrosion, and encourage environmentally favorable structure ways.

Q10. What’s the unborn outlook for HDPE geomembrane demand in India?

It’s anticipated that as structure systems increase and environmental protection laws come more strict, demand would rise snappily.