In the modern era of advanced electronics, electromagnetic interference (EMI) has become a critical concern for engineers and designers. EMI can disrupt the normal operation of electronic devices, leading to signal degradation, malfunction, and reduced performance. To ensure the reliability and functionality of electronic devices, it is essential to implement effective design strategies to mitigate EMI issues.

1. Optimize PCB Layout Design

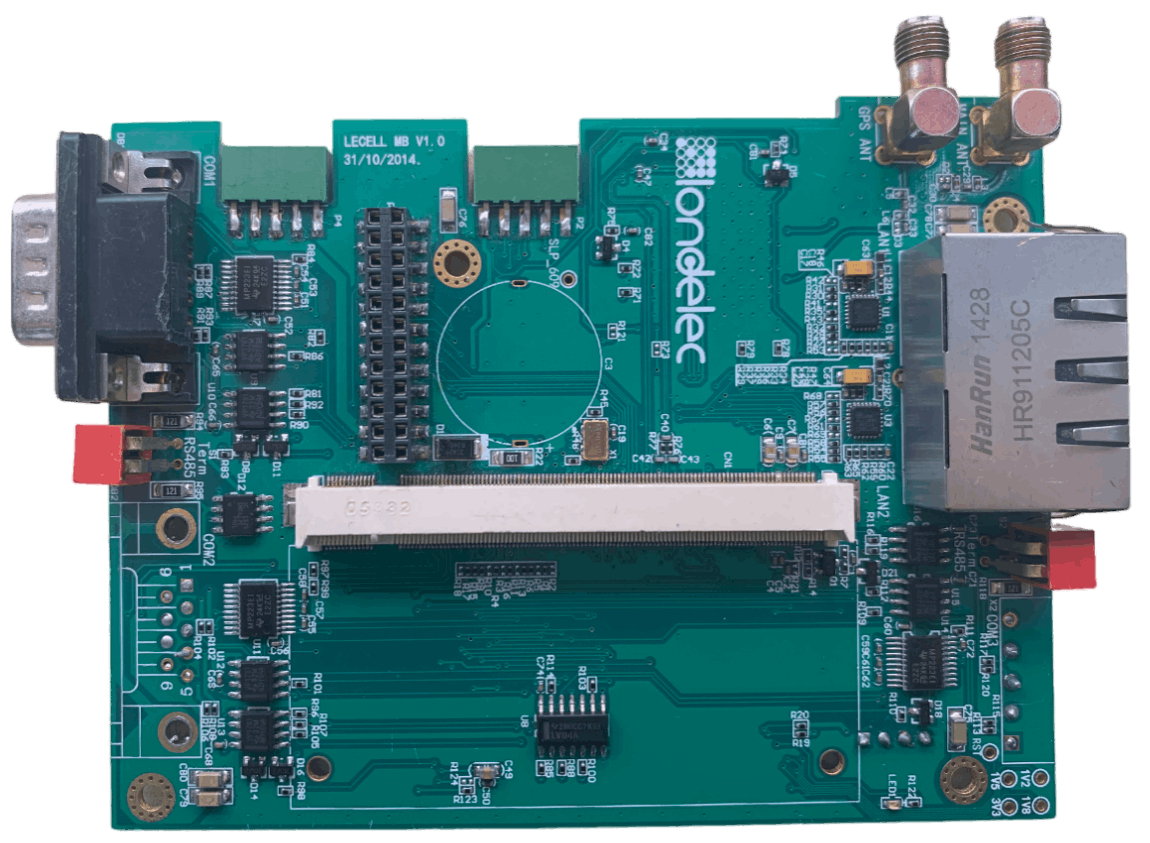

The printed circuit board (PCB) layout is a fundamental aspect of electronic device design, and it plays a crucial role in minimizing EMI. One of the key principles is to separate high – speed and low – speed signal traces. High – speed signals are more prone to generating EMI, and by keeping them away from low – speed signals, the risk of crosstalk and interference can be significantly reduced.

Another important factor is the proper placement of components. Components that generate a large amount of EMI, such as switching power supplies and microcontrollers, should be placed in areas that are isolated from sensitive components. Additionally, the use of ground planes and power planes can help to reduce EMI by providing a low – impedance path for return currents. The ground plane should be continuous and have as few breaks as possible to ensure effective shielding.

For example, in a circuit board for a wireless communication device, the RF (radio frequency) components should be grouped together and separated from the digital components. This separation helps to prevent the digital signals from interfering with the RF signals, which are crucial for the device’s communication performance.

2. Implement Shielding Techniques

Shielding is an effective method for containing EMI within an electronic device and preventing it from radiating outwards. There are several types of shielding materials and techniques that can be used. Conductive enclosures, such as metal cases, can be used to surround the electronic components and block the electromagnetic fields. These enclosures should be properly grounded to ensure that the EMI is conducted away from the device.

Internal shielding can also be applied at the component level. For instance, shielding cans can be placed over individual components, like integrated circuits, to isolate them from external electromagnetic interference. These shielding cans are usually made of conductive materials and are soldered to the PCB’s ground plane.

In automotive electronics, where there are numerous electronic devices operating in close proximity, shielding is essential. The engine control unit (ECU) and other sensitive components are often shielded to protect them from the EMI generated by the vehicle’s electrical system, such as the ignition system and alternator.

3. Select Appropriate Filtering Components

Filters are an important part of EMI suppression. They can be used to remove unwanted frequencies from the electrical signals, thereby reducing the potential for EMI generation. Common types of filters include low – pass filters, high – pass filters, band – pass filters, and notch filters.

For power supply lines, low – pass filters are commonly used to suppress high – frequency noise. These filters allow the low – frequency power signals to pass through while attenuating the high – frequency components that can cause EMI. Ferrite beads are also widely used in power and signal lines. They act as high – frequency resistors, dissipating the unwanted high – frequency energy as heat.

In a computer power supply, a combination of capacitors and inductors is used to filter out the noise from the AC input and provide a clean DC output. This filtering not only improves the performance of the computer but also reduces the EMI generated by the power supply, which could otherwise interfere with other nearby electronic devices.

4. Ensure Proper Grounding

Grounding is a critical aspect of EMI reduction. A good grounding system provides a reference point for electrical signals and helps to drain away any unwanted electrical charges. There are different types of grounding techniques, including single – point grounding, grounding, and hybrid grounding.

Single – point grounding is often used in low – frequency circuits. In this method, all the ground points in the circuit are connected to a single common point, which helps to prevent ground loops and reduce EMI. grounding, on the other hand, is more suitable for high – frequency circuits. It involves connecting multiple ground points directly to the ground plane to minimize the impedance at high frequencies.

In a large industrial control system, a well – designed grounding system is essential. The various sensors, controllers, and actuators need to be properly grounded to ensure that the electrical signals are stable and that EMI is minimized. A poor grounding system can lead to false readings, system malfunctions, and increased EMI emissions.

5. Conduct Thorough EMI Testing and Simulation

Before the final production of an electronic device, it is crucial to conduct comprehensive EMI testing and simulation. EMI testing can be carried out using specialized equipment, such as spectrum analyzers and near – field probes, to measure the electromagnetic emissions of the device. By identifying the sources of EMI during the testing phase, designers can make the necessary modifications to the design to reduce the interference.

Simulation tools, such as electromagnetic field simulation software, can also be used in the design process. These tools allow designers to predict the EMI performance of the device before physical prototypes are built. By simulating different design scenarios, designers can optimize the layout, shielding, and filtering components to achieve the best EMI suppression results.

For example, in the development of a new smartphone, the design team will conduct multiple rounds of EMI testing and simulation. They will test the device in different operating modes and environments to ensure that it meets the relevant EMI standards and does not interfere with other communication devices.

In conclusion, addressing Electronic Device EMI issues requires a comprehensive approach that encompasses PCB layout design, shielding, filtering, grounding, and testing. By implementing these five effective design tips, engineers and designers can significantly reduce EMI and ensure the reliable operation of electronic devices. As the demand for more advanced and compact electronic devices continues to grow, the importance of effective EMI mitigation strategies will only become more pronounced.

Read Also